Want to Impact Asset Modernization? Here Are 5 Critical Simulation Needs

Digital mission engineering (DME) and simulation are the keys and here’s why.

June 29, 2021

Steve Bleymaier

Across the federal, aerospace, and defense (FA&D) ecosystem, accelerated modernization through digital transformation and simulation remains a critical priority to ensure warfighters stay ahead of the threat.

Over 90% of aerospace and defense executives intend to reinvent their digital business. Yet fewer than 10% have made impactful progress. Closing this gap represents a significant competitive advantage for warfighters and aligns with the U.S. DoD Digital Engineering Strategy. The faster it’s closed, the greater the benefit.

Model-based approaches are maturing across the acquisition process thanks to integrated simulations that scale from physics-based simulations of components to entire missions. Such simulations will play a critical role in accelerating digital transformation by delivering state-of-the-art technology to the warfighter faster, with fewer resources and a higher probability of success. This type of digital mission engineering (DME) has been calculated to deliver an overall program acceleration of 6x.

Whatever the program, from the development of trusted and assured microelectronics to hypersonics, realizing these benefits requires five capabilities.

1. Deployable Across the Acquisition Process

Intuitive interfaces, workflows, and computational power now make it easy for almost any engineer — novice or expert — to significantly expand analysis of alternatives studies with near real-time results, dramatically expanding the ideation process.

In manufacturing, research highlights a 25% greater improvement in overall equipment effectiveness (OEE).

Similar technology is now being used to optimize operations and sustainment through physics-based digital twins, driving operational availability while reducing maintenance costs.

2. Integration from the Microchip to the Mission

Today, a hierarchy of simulation tools is used from component design to mission assessment. Unfortunately, in many cases, the tools used at each level — components, systems, systems of systems, and missions — lack integrated digital connectivity.

With digital mission engineering, a pervasive simulation environment that integrates all scales of models is possible. The DME helps establish a continuous high-fidelity digital thread from the microchip to the mission that predicts operational outcomes much more effectively and identifies critical issues earlier. The result is that required capabilities are delivered to the warfighter faster and much more affordable.

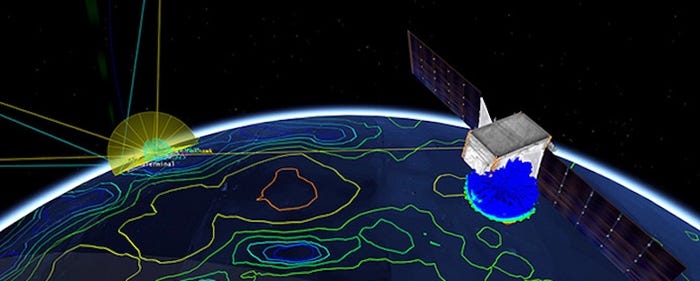

Integrated across all operational domains, DME enables engineers to simulate assets and predict how they perform in a mission’s operational environment.

For example, DME continues to impact numerous high-profile government programs, including NASA’s OSIRIS-Rex mission, where an uncrewed spacecraft recently collected samples of minerals from a potentially hazardous asteroid projected to re-enter the solar system the end of the next century. Understanding the minerals’ chemical and physical characteristics will prove vital for managing the threat. Leveraging DME, engineers determined the spacecraft’s nominal trajectory and complex maneuvering sequence that allowed it to safely land on the asteroid’s surface.

3. Accuracy and Validation

With lives and mission success at stake, physical testing has been the go-to method for validating mission-critical and safety-critical performance. However, FA&D leaders realize simulation has evolved to validate complex military systems’ real-world capabilities rapidly and cost-effectively in a virtual world — thus complementing physical testing while significantly streamlining development processes.

For example, simulation is being used to streamline the development of avionics for U.S. military aircraft.

4. Open and Collaborative Environment

Modern military system acquisition involves an ecosystem of heterogeneous multitool simulation capabilities, often spread across suppliers, geographies, and functions. This requires open interfaces that are interoperable with multiple enterprise capabilities for product lifecycle management and resource planning. The days of a restrictive singular-provider simulation environment that is unique or tied to a specific program are over.

Fortunately, a new era of open and interoperable simulation platforms has arrived, providing simulation and process data management, performing integrated and customizable enterprise workflow chaining and optimization, and ushering in a gateway to high-performance computing capabilities.

The U.S. Army has increased access to and scalability of complex government simulation code due to a customizable simulation environment.

Organizations must embrace these new capabilities and ecosystem opportunities to amplify the impact of a simulation further.

5. Workforce Enablement

Enterprises are struggling to recruit engineers with the skill sets to drive digital transformation while simultaneously addressing knowledge loss due to a retiring workforce.

By teaming with approved commercial providers and their simulation centers of expertise, leveraging expert-led, application-relevant, and enterprise-scalable training with highly reliable technical support and services, engineers can be onboarded faster. Additionally, both new and existing engineers upskill much more quickly — accelerating the adoption of cutting-edge simulation capabilities.

Federal aerospace and defense leaders can benchmark their own DME maturity against these five critical capabilities and determine what they can do in each area to accelerate — ensuring the warfighter stays even further ahead in an ever-evolving threat environment.

Retired U.S. Air Force Brig. Gen. Steve Bleymaier is the vice president for global strategy and government programs, federal aerospace, and defense at Ansys. Previously, he spent more than 28 years with the U.S. Air Force leading strategic initiatives in aircraft sustainment, supply chain, and logistics. (Image Source: Ansys, DME)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)