How Apps Can Modernize Inspection and Maintenance

The Ohio train derailment demonstrates the need for updated inspection and maintenance processes, which could involve using mobile apps.

On February 15, 2023, the town of East Palestine, OH, was rattled by a catastrophic train derailment. The incident resulted in the release of hazardous materials, evacuation of nearby residents, and significant environmental damage.

According to a CBS news report, an estimated 43,700 animals perished in the three weeks following the incident, with many fish dying instantly. In addition, approximately 4,700 residents in the area reported illness due to concerns over exposure to the hazardous materials that were released from the burning tankers.

These staggering numbers make it clear that this tragedy served as a powerful reminder of the critical importance of train safety and inspections. The incident highlights the potential environmental and health consequences of train accidents and the need for the railroad industry to continuously improve its inspection and maintenance processes. All of these factors underscore the urgency for the industry to invest in modern technologies that can enhance the inspection process and prevent future incidents.

Importance of Ongoing Inspections and Maintenance

In the railroad industry, regular inspections are required to verify the integrity and safety of tracks, switches, signals, and other equipment. These inspections are typically performed by trained inspectors who visually examine the equipment and perform other tests to detect any abnormalities.

In the case of the Ohio train derailment, the incident was attributed to an overheated wheel bearing. The National Transportation Safety Board (NTSB) stated that the Ohio train derailment was "100% preventable," underscoring the importance of rigorous inspection and maintenance protocols in the railroad industry. Regular inspections can facilitate the detection of potential issues like overheated wheel bearings and other malfunctions, such as broken rails and worn-out tracks, that may pose a safety hazard. By detecting these issues early, maintenance personnel can be promptly dispatched to address the problem and prevent it from escalating into a significant safety concern.

Regular inspections and maintenance can also improve the overall safety and reliability of the railroad system. When issues are identified and repaired proactively, trains can operate safely and efficiently, reducing the risk of delays, disruptions, and accidents.

Improvements to Railroad Inspection and Maintenance

The Federal Railroad Administration (FRA) has announced enhanced track inspections in response to the Ohio derailment to prevent future incidents. The FRA will conduct additional inspections of tracks and equipment, increase the frequency of inspections, and use advanced technology to detect potential hazards.

Railroad inspections can involve a variety of tasks, such as inspecting tracks, bridges, tunnels, signals, and other equipment. These inspections are usually performed by a team of inspectors who walk along the tracks and visually inspect the components for any defects or issues. They also utilize specialized equipment, such as ultrasound and impact-echo devices, to detect internal rail defects. Additionally, thermographic cameras are employed to identify hot spots that may signify potential failures in components such as bearings or electrical connections.

While these visual inspections are essential in the railroad industry, they involve examining each component for defects or other issues. Such manual data collection requires a great deal of attention to detail and can be time-consuming. Inspectors may also be working under adverse weather conditions or in challenging environments, which can increase the likelihood of errors. Additionally, human error is always a possibility, as inspectors may overlook defects or record them imprecisely, which can result in safety hazards. However, the use of technology can enhance the efficiency and precision of inspections, and this is where modern inspection apps come into play.

Key Features of Modern Inspection Apps

Inspection apps can provide a range of benefits to the railroad industry. They can improve the speed and accuracy of inspections, enhance real-time data collection, and facilitate information sharing among inspectors and maintenance personnel.

Faster Inspections

Inspection apps possess the capability to expedite inspection procedures by automating numerous inspection tasks, such as data collection and form completion. Consequently, these applications can optimize inspection timeframes and enable inspectors to allocate their resources toward other crucial tasks.

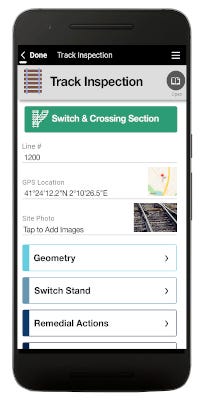

For example, instead of manually recording track defects on a paper form, an inspector can use an app to scan a QR code on the track and record the defect using their smartphone. This process is faster, more accurate, and less prone to errors.

Real-Time Data Collection

Collecting real-time data during inspections is another advantage of inspection apps. This data can be transmitted to a central database, providing instant feedback on the inspection results. Instant feedback enables the identification of potential hazards and facilitates immediate corrective action.

An example of how inspection apps can improve the inspection and maintenance process is when an inspector detects a track defect, they can record the location and severity of the defect and instantly transmit such data to a centralized database. Maintenance personnel can then receive alerts regarding the issues and promptly respond. This efficient exchange of information enables quick corrective action, mitigating the risk of potential safety hazards.

Information Sharing

By enabling easy information sharing between inspectors and maintenance personnel, inspection apps can enhance communication, minimize errors, and optimize the inspection process. With inspection apps, inspectors can easily share data, reports, and photos with other team members, making it easier to collaborate and address any issues that arise.

In the case of railroad inspection, an inspector can utilize an inspection app to capture a photo of a track defect and append it to the inspection report. The inspection report can be shared with maintenance personnel, who can utilize the photo to identify the problem and undertake corrective measures.

Conclusion

The derailment of the train in Ohio was a heartbreaking reminder of the crucial role that train safety and inspections play in preventing catastrophic events. Even though the railroad industry has strict inspection and maintenance protocols, there is always scope for progress. That's where inspection apps come in—they can be a game-changer for the industry. By utilizing these cutting-edge technologies, the railroad industry can overcome the shortcomings of traditional inspection methods and take a giant leap forward in improving safety, reducing accidents, and protecting the environment and citizens it serves.

About the Author(s)

You May Also Like