You Can Use VR to Optimize Your Plant

A new hardware and software package from VRgineers, R3DT, and Leap Motion lets engineers experience virtual simulations of factories and manufacturing processes.

September 25, 2019

|

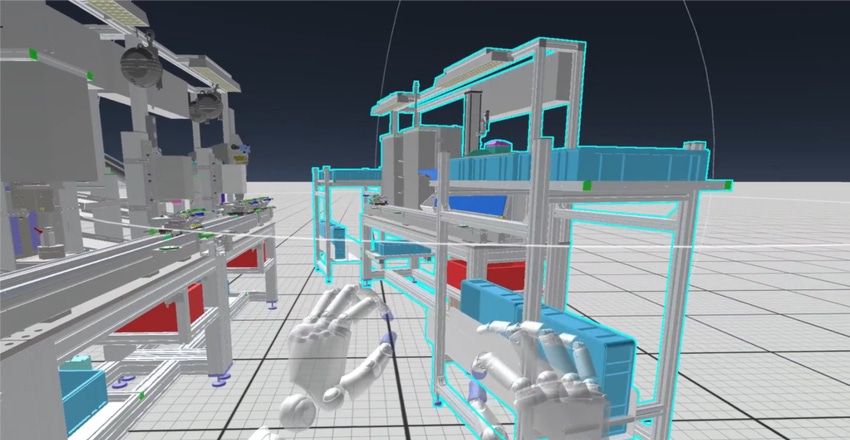

Engineers can use R3DT's simulation software (shown) to prototype factory layouts and run process simulations in VR before physical installations are made. (Image source: R3DT) |

Engineers interested in leveraging virtual reality for industrial planning are getting a full hardware and software package dedicated to streamlining how production lines and factories are designed and developed.

Enterprise-focused VR hardware company VRgineers, hand tracking technology company Leap Motion, and VR software developer R3DT have entered into a partnership to supply an all-in-one VR solution for plant design and optimization. The system will incorporate R3DT's VR industrial engineering software with VRgineers' XTAL headset, which integrates Leap Motion's hand tracking technology.

“Virtual prototypes, unlike physical ones, are easy-to-use and inexpensive,” Adam Schneider, co-founder and managing director of R3DT, said regarding the partnership. The goal is to facilitate design, remodeling, and streamling of production zones in factories for both efficiency and ergonomics without the need to build physical mockups.

Users will be able to create scale virtual models, navigate them as if they were walking through the actual space, and run simulations of assembly and manufacturing processes. All together, the package should allow engineers to experience both the factory space and their workflows and make necessary adjustments before physical installations are in place or before a plant is even built.

The 5K resolution of the XTAL, coupled with the controller-free gesture control enabled by the headset's integrated Leap Motion controllers, allows users to create layouts in R3DT's software that are both very detailed in resolution and also have an intuitive, hand guesture-based control scheme.

RELATED ARTICLES:

The XTAL eadset from VRgineers is the only commercially-available VR headset to integrate Leap Motion's sensor technology. VRgineers maintains an enterprise focus on its products and designs them with engineering workflows in mind over entertainment – hence the emphasis on high-resolution graphics (the headset also has a very wide 170-degree field of view) and controls.

“Smart companies use resources wisely: VR shortens time-to-market because it makes it possible for companies to design, test and make changes fast and effectively, while allowing experts to maximize their productivity Marek Polčák, co-founder and CEO of VRgineers, said in a press statement.

This is the first major product announcement to come from Leap Motion since it was purchased by UK-based Ultrahaptics earlier this year. The company has been on a rocky road since first introducing its sensor technology – capable of accurately tracking hand movements down to specific fingers and joints – and famously rejected acquisition offers from Apple. Ultrahaptics works in a similar realm as Leap Motion and has developed sensor technology that uses ultrasonic waves to track users' hand movements and also provide a sense of touch and texture when interacting with devices using gesture control.

Chris Wiltz is a Senior Editor at Design News covering emerging technologies including AI, VR/AR, and robotics.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)