Is a Single Production Line Better Than Multiple Ones? Organizations Need to Know

A PLE approach allows companies to build a product line portfolio as a single production system.

May 19, 2021

Product Line Engineering (PLE) has a growing role in systems engineering, digital engineering, and manufacturing production processes. This point was emphasized at a recent International Council on Systems Engineering (INCOSE) conference. INCOSE is a professional organization founded to disseminate the interdisciplinary principles of and advance systems engineering practice.

A PLE approach allows companies to build a product line portfolio as a single production system rather than a multitude of individual products. As a result, this approach promises big improvements over the traditional product-center engineering strategy.

To learn more about the shift from product-centric to product line engineering, Design News sought out one of the founding fathers of the PLE field, Dr. Paul Clements, VP of Customer Success for BigLever Software. What follows is a portion of that conversation.

Design News: How does the structure of an organization affect the PLE process – or vice versa?

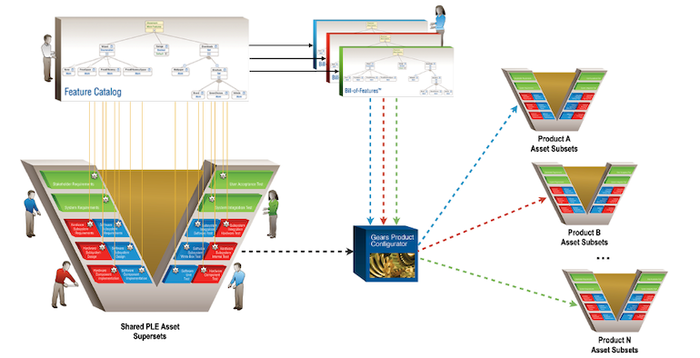

Dr. Paul Clements: One of the core tenets of Feature-based PLE is the concept of a PLE Factory, in which an automated tool, called a configurator, processes a set of engineering artifacts, called shared assets, using the feature selections that define a product in the product line. The benefits for which Feature-based PLE is known to accrue from having everyone carry out all development activities on the shared assets and not on the engineering artifacts associated with an individual member product. The fruits of those activities are applied, by the configurator, to all of the products to which they apply, thus magnifying the productivity and effectiveness of the engineers. To put it more succinctly, all work in Feature-based PLE happens inside the digital PLE Factory and not on the product instances that come out of the Factory. This should make it clear why organizational structure is so important. Feature-based PLE asks that you take people out of product teams and move them into the PLE Factory.

Design News: What can be done to enable companies with complex or rigid organizational structures to follow a PLE process?

Dr. Paul Clements: What we find is that organizations employing Feature-based PLE typically enjoy a productivity boost for their engineers of 200 percent to 300 percent. That is, their engineers become 2-3 times as effective as they were before PLE. This translates into cost avoidance, higher quality, reduced time, replacement of low-value work with high-value work, innovation, and more. Often, this value proposition is sufficient to motivate companies to change their organizational structures and processes.

Further, the change is not, upon closer inspection, a radical one. All it takes is a mindset or perspective shift to regard the PLE Factory as the project — the project that needs to be managed (just like any other), that can be made Agile (just like any other), that must be staffed and resourced (just like any other). It’s just that this project is one that delivers an engineering capability — the capacity to generate products in a product line.

Design News: Do you have an example or case study of the successful implementation of this approach?

Dr. Paul Clements: We do have a case study where a company said they failed to implement the recommended organizational structure and came to regret it: "[We] first tried to instill the product line approach throughout the… program by senior management fiat. Despite sincere management intent, people doing the day-to-day work were allowed to drift back into configuration-centric activities and mindsets. It was only after re-organizations occurred that re-structured the customer-specific teams and moved the resources into product-line-wide shared asset groups did the transition finally find traction. [We] did a good job launching the product line, but the institutionalizing was not fully successful until after reorganization. The delivery was eventually successful, but not without an alarming amount of re-work.”

That was from a paper published by Lockheed Martin. In it, they recounted their experience leaving the organizational structure in its pre-PLE form and simply telling people that their work (in project silos) should benefit the whole product line. (Image Source: Bolander/Clements, Biglever)

John Blyler is a Design News senior editor, covering the electronics and advanced manufacturing spaces. With a BS in Engineering Physics and an MS in Electrical Engineering, he has years of hardware-software-network systems experience as an editor and engineer within the advanced manufacturing, IoT and semiconductor industries. John has co-authored books related to system engineering and electronics for IEEE, Wiley, and Elsevier.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)