Putting a New Face on CAD Interoperability

July 10, 2011

For more than a decade, it's been one of CAD users' more vehement complaints: 3D models created in one CAD system can't readily be used by another. While the CAD interoperability problem has by no means been sidelined, the industry has gained significant ground in addressing the issue via new technologies and through modifications to the design workflow that facilitate cross-platform collaboration.

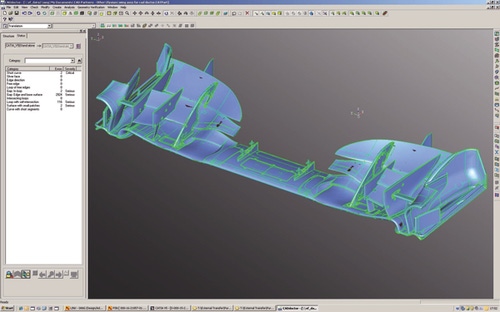

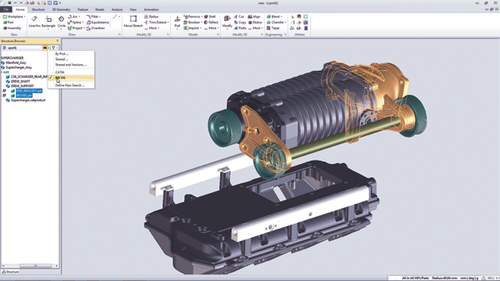

New visualization and collaboration tools that foster the exchange of lightweight models (meaning 3D geometry without all the design intelligence) have been instrumental in helping companies better exchange multi-CAD data without the hangover of traditional platforms. In addition, new technologies advancing the concept of direct modeling, along with reorienting design workflows so that only critical parts of a design, not full assemblies, are translated between parametric-based offerings, are other tactics easing the interoperability burden.

The solutions couldn't come at a better time. In today's global economy and with the rise of outsourcing, engineers are just as likely sharing design information with peers within their own companies as they are with suppliers, partners, and customers located across the globe. Needless to say, with few exceptions -- large automotive OEMs, perhaps -- it's the rare instance when all of the parties within this extended and dispersed product development ecosystem can mandate the use of the same CAD tool, hence enjoy a fairly seamless exchange of CAD data.

To make matters even more vexing, companies across all industries are consolidating, and this age of merger-and-acquisition activity can leave companies in the lurch when they try to meld product development organizations. Not only do they have to integrate people and processes, but trying to standardize on a single CAD tool or a perfect a way to exchange CAD models created by different tools can be quite a challenge, to say the least.

Finally, all of the R&D effort that vendors have poured into evolving CAD tools over the last few years has not gone unnoticed. Now, more so than in the past, companies are willing to consider swapping out their legacy CAD systems for fresh offerings. When they do that, the new system is typically used for new designs, but there is still a requirement to keep a connection to the legacy CAD data.

"CAD interoperability is not just an ongoing issue -- it's a growing issue," says Paul Brown, senior marketing executive for NX for Siemens PLM Software, in an interview. "It's not something that's gone away. It's become even more of an imperative for companies to figure out how to work in this area."

Multi-CAD on the rise

Recent research from Aberdeen Group highlights just how prevalent the use of multi-CAD has become, and how critical the need for ongoing solutions to the interoperability problem. According to a December 2010 survey of 269 companies, 82 percent of respondents reported using three or more CAD formats in their design processes, with 42 percent using five packages or more. By having to juggle different CAD systems, companies face several issues -- the worse being an inability to leverage the different models or, alternatively, having to deal with data translation hiccups and the inefficiencies of not being able to effectively manage disparate CAD files. It's not difficult to see the business impact of such bottlenecks: wasted time and poor product quality.

"So much information is now embedded into a CAD file that losing that data becomes painful," says Michelle Boucher, senior research analyst at Aberdeen and author of the report, "Working with Multi-CAD? Overcoming the Engineering Collaboration Bottleneck."

"Engineers are under such huge pressures to meet development schedules, they don't have time to be remodeling, rebuilding, and recreating work that is done by someone else."

They may not have the time, but the reality is that it's a responsibility they can't avoid. According to the 2010 Collaboration & Interoperability Report by LongView Advisors, 41 percent of professionals in product design, development, and engineering play some sort of role in CAD interoperability or data exchange activities. That's a lot of highly paid talent spending valuable time doing relative grunt work compared to investing their time and effort in product innovation, says David Prawel, president of Longview Advisors.

Next Page: Forgiving and flexible CAD

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)