CAD Primed for Plastic Parts Design

April 11, 2012

Two leading CAD vendors have augmented their portfolios with offerings aimed at easing the design and manufacturing of injection molded parts.

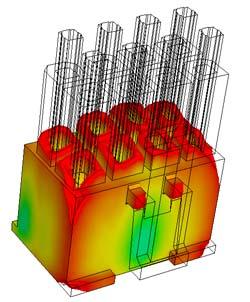

As part of the 2013 refresh of its digital prototyping suite, Autodesk bolstered the capabilities of Moldflow, its injection molding simulation offering directed at plastics design. The company also added a new module intended to deliver real-time feedback on the impact of design decisions on manufacturability, cost, and sustainability.

SolidWorks stepped up to the plate with its first tool specifically targeted at plastics applications. SolidWorks Plastics runs inside the CAD tool and is based on technology from SIMPOE SAS, a partner specializing in plastics injection molding simulation software.

Bob Williams, Autodesk's solution marketing manager for simulation, told us that it is critical for the digital prototyping suite to address the more widespread use of plastic parts in designs, along with the increased sophistication of materials and manufacturing processes. For instance, as the drive toward lighter vehicles in the automotive sector translates into the substitution of plastic parts for metal ones, stronger, more durable plastic parts must be produced.

To that end, Autodesk Simulation Moldflow now offers enhanced long fiber and crystallization behavior capabilities to help users understand and predict how the injection molding process affects materials. Williams said this simulation capability helps develop a stronger component without significantly increasing its weight.

About the Author(s)

You May Also Like