5 Products That Look Totally Different Through an Industrial CT Scanner

Get an inside view of some of today's most popular products thanks to this industrial CT scanner built for engineers.

Austin Carder

December 13, 2022

5 Slides

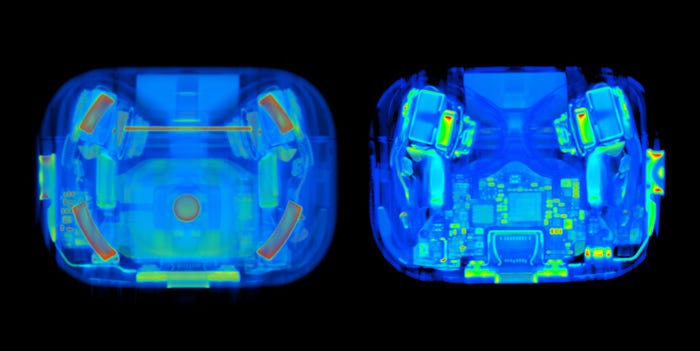

Industrial CT scanners use X-rays to reveal the inner workings of complex devices in three dimensions. With the help of Lumafield’s Neptune industrial CT scanner, we find that there’s more than meets the eye within these 5 small feats of engineering.

Lumafield has developed the Neptune scanner and cloud-based software to be easy enough to use so that engineering teams can rely on them as front-line tools. The approach offers visibility into products as well as AI-driven tools that highlight problems and generate quantitative data.

About the Author(s)

Sign up for the Design News Daily newsletter.

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)