4D Printing Self-Assembled Shapes Using Shape Memory Plastics

November 19, 2013

Last spring we told you about MIT's Skylar Tibbits, whose TED talk made the idea of 4D printing famous. The process self-assembles a 3D-printed object underwater using Stratasys's materials and its Objet Connex 500 Multi Materials inkjet 3D printer.

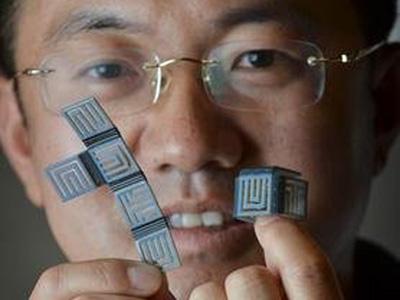

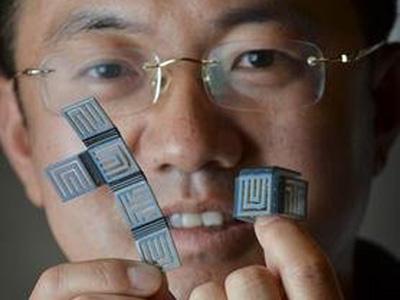

Researchers at the University of Colorado Boulder have combined 3D printing on the Objet Connex multi-material 3D printer with making shape-memory composites, calling that process 4D printing. By incorporating shape memory polymer fibers into a matrix of the 3D printer's composite multi-materials, an object can be printed in one shape and change its shape later, such as self-assembling into a cube. The team, led by associate professor of mechanical engineering H. Jerry Qi, detail their work in an open-access article published in Applied Physics Letters. Other authors are postdoctoral research associate Qi Kevin Ge, and Martin L. Dunn, a professor at the Singapore University of Technology and Design.

In the article, the team describes how they designed and printed flat laminate materials that can be thermomechanically programmed to form a variety of complex, three-dimensional shapes, such as twisted, coiled, and bent strips of material, or sheets that fold themselves into cubes or various curves. When the material is heated again, these assembled shapes can then be returned to flat sheets.

The team calls its new materials design printed active composites. The specific shapes and their behavior, such as folding, curling, twisting, and stretching, are determined by the architecture of the fibers and how they are designed, such as their shape, size, location, and orientation in the matrix. This architecture is specified within a CAD file and the composite is 3D printed directly from that file.

The researchers emphasizes that their materials are different from Tibbits' in part because theirs are soft: the glassy polymer fibers are embedded in an elastomeric matrix. But they also say that "one can extend the concept to general spatial variations of materials properties and use computational design tool such as shape and topology optimization to design the layout of the materials in the composite, as well as exploit instabilities to create large configurational changes."

An example application for the technology includes a flat solar panel that could change itself into a more compact shape for shipping, and then revert back after it's received. The Air Force Office of Scientific Research and the National Science Foundation provided funding for the research.

Related posts:

About the Author(s)

You May Also Like