From Photo to 3D Model With Autodesk Photofly

July 1, 2011

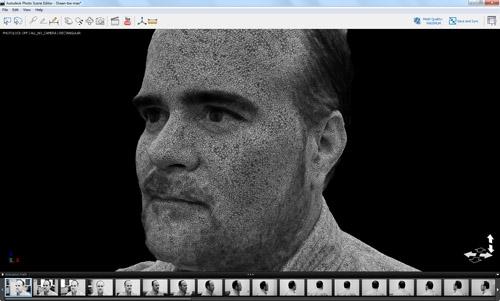

Leave it to Autodesk Labs to come out with the coolest stuff. One of the newest projects in its array of whiz-bang technologies is Project Photofly, which is being dubbed a "Photo Scene Editor" for creating 3D models from photographs using a Web-based service.

From a consumer perspective, the service has high utility and a huge fun factor, as anyone with a standard point-and-shoot digital camera can create near-accurate 3D models simply by taking and uploading a bunch of photographs to the service running in an Autodesk-run cloud. Once completed, the 3D models can be manipulated using any of Autodesk's design programs (Inventor, AutoCAD, 123D), and would-be designers can directly share their creations via built-in share tools for uploading to YouTube and other social sites. Autodesk says about 40 pictures are needed to produce a 3D model.

Beyond the consumer applications, though, a service like this can have huge applicability for manufacturing and commercial product design applications. In an interview, Brian Matthews, vice president of Autodesk Labs, says companies are already experimenting with the technology to build digital models of buildings to do energy modeling and to more easily create 3D models of custom manufacturing equipment as part of a design exercise to plot out a replacement.

Perhaps even more exciting is the potential for pairing the Photofly technology with 3D printing technology, which is rapidly coming down in price, and becoming much more familiar and accessible to smaller companies and DIY inventors. Simply by taking and uploading a series of photos, Matthews says, companies have a tool for easily personalizing a product to fit an individual, which has applicability for designing products like hearing aids, teeth implants, even scanning individual people. Introduce CNC milling machines into the mix, and you catapult this vision of mass customization to a much grander scale, according to Matthews, letting companies custom build products from watches to cars using this pairing of technology.

Here's how the technology works: Users take a bunch of photos of the desired object from a variety of angles, then upload the photos to the program and hit the submit program to send it to the Autodesk cloud. Matthews says the first step in the computation process is to create a draft model using triangulation to determine where the photos are taken in relative space. Once that draft mesh is created and the user is happy with the result, the model is sent back to the cloud to do heavy computation, and a 3D triangular mesh is built.

As with all projects on Autodesk Labs, this is a technology preview and not a commercially viable product. But from the looks of things, companies and individuals are ready to experiment as 3D modeling technologies move well beyond the traditional domain of CAD.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)