Using Software to Model a Battery’s Lifetime Performance

When exploring energy storage opportunities, grid operators should keep battery modeling top-of-mind.

August 7, 2017

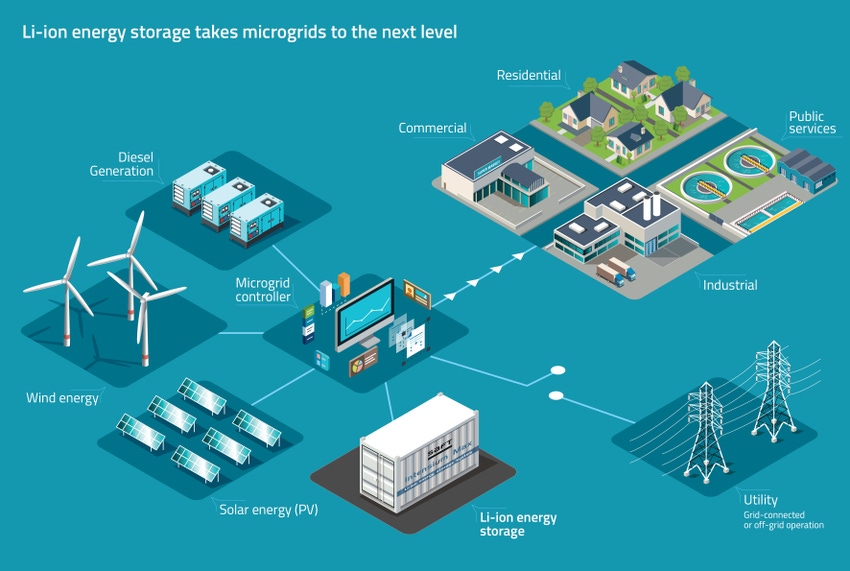

As the market for energy storage systems expands, microgrids in remote communities have become an attractive opportunity for the deployment of renewable generation with storage. Because these communities generally rely on diesel generation, and often have logistical challenges for fuel delivery, fuel savings is a fundamental objective.

Reducing fuel consumption in microgrids is just one of many targets obtainable with battery modeling. Battery modeling is a known technique, yet it continues to evolve to better address the demands of our digital society. These simulations are critical to the project development process, as they deliver insights into energy storage applications ahead of deployment. They also assist with determining how much power and energy is required.

Coupling High-Level Modeling with Complex Simulations

High-level modeling of an entire microgrid is an excellent exercise to check the viability of renewables with storage. One example of the tools that can be used is a commercial software suite derived by the National Renewable Energy Laboratory. Such modeling is typically based on hourly data and the granularity of energy storage system dispatch is correspondingly coarse.

|

Saft’s Matlab-Simulink models paired with HOMER Pro Software offer a robust assessment of energy storage system capabilities. |

High-level modeling is feasible, even with minimal data input. For example, an initial model of a microgrid can be constructed with minimal inputs, such as the coordinates of a village in Northern Canada having a peak load of 130kW in January. With this information, high-level modeling builds a typical load profile and offers the ability to download location-specific solar or wind resources. The software then quickly performs multiple simulations to optimize the renewable energy power rating, along with an appropriate level of energy storage. The results illustrate fuel savings and, if sufficient inputs are detailed, return on investment (ROI).

When it comes to modeling the detail of these systems, such as bridging between multiple diesels in a large microgrid, or optimizing the set points for operating with diesels in a smaller microgrid, more precise modeling is required. High frequency data, at least as granular as every 10 minutes, is valuable. This modeling provides insights into system operation, including diesel synchronization and cool-down times, to minimize diesel starts, maximize fuel savings and optimize battery life.

Precise modeling requires more detailed inputs and time to optimize the dispatch methodology. Thus, coupling high-level with precise modeling offers a cohesive, informed glimpse into an energy storage system to facilitate evaluation of the viability of a project, as well as a detailed strategy required to ensure project success.

Data to Consider for Battery Modeling

The data requirements for modeling microgrids are relatively simple, including load, renewable resource, diesel configuration, and information on any dispatchable loads, such as electric water heaters. The next step beyond microgrids is to weak grids such as islands, where energy storage can play a critical role for grid stabilization, addressing both the variability of renewables and other disruptions, such as generator trips.

|

Saft’s megawatt scale Li-ion containerized energy storage systems for grids and renewable energy sources smooths intermittent generation and ramp rates, as well as supports peak management and voltage support. |

Battery modeling for weak grids is typically based on frequency response, where the energy storage output varies constantly as a function of the network frequency, charging when the frequency is high and discharging when the frequency is low. In this case the input—grid frequency—is simple, but the choice of parameters, including frequency deadband, droop slope, and the all-important state-of-charge-management function, is much more complex. It is also important to remember the simulation input (frequency) will be altered by the output (charge or discharge power). Furthermore, available data may not necessarily be reflective of the grid’s planned development, particularly ongoing deployment of renewables. Performing additional modeling when the system is in operation and periodically throughout life, and adjusting operating parameters accordingly is crucial as minor adjustments may greatly extend a battery’s lifecycle.

Data with a high sampling rate is beneficial for accurate modeling, providing better certainty of value for an energy storage investment. Moreover, a sampling of grid data from a week during each season is recommended, to make sure that seasonality effects are properly considered. Capturing data during a major frequency event is also effective.

Supplementary Battery Modeling Capabilities

For islands in particular, energy storage systems are often called upon to provide black-start capabilities. Following a system-wide blackout, a well-designed energy storage system can energize a path to a generator and then provide control power for starting. Then, as the transformers, feeders and transmission lines of the network are reenergized, the energy storage system can respond to frequency shifts to keep the entire system functioning. In the energy storage system planning phase, modeling can help make sure batteries always maintain a reserve of energy for black starting.

To be effective, battery models should run the same algorithms as battery management systems, mimicking real battery behavior. Efficiency losses and thermal management should be included, to make sure the system’s cooling is adequate. And, since battery losses increase with age, it is vital that models can reflect the end-of-life situation for the system. This requires not only that these models accept inputs for different stages of battery life, but that they also include aging outputs. Only then can there be certainty regarding the lifetime of the system and its end-of-life characteristics.

Added Value for Energy Storage Systems

When exploring energy storage system opportunities, grid operators should keep battery modeling top-of-mind – and initiate conversations about simulations at the forefront of their strategy to maximize cost savings throughout the entire process.

|

Saft’s Li-ion energy storage solutions help stabilize grids of all types and sizes. |

Taking the time to run battery models opens the door for quantifying energy storage benefits, including fuel savings in microgrids. It also provides an opportunity to grasp the project’s ROI potential. With today’s data-driven society, immense amounts of statistics are collected daily in all industries. Keeping tabs on such numbers will help grid operators comprehend the real value that energy storage systems provide.

Jim McDowall is the business development manager for Saft, a developer and manufacturer of batteries used in transportation, industry and defense.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)