Vicor’s 48-Volt Power Architecture Can Support 12-Volt Systems

New 48-volt vehicles don’t need a separate 12-volt battery to support lower-voltage systems.

Electric power module supplier Vicor Corp. is pointing out that automakers can enjoy the benefits of 48-volt electric systems in their vehicles without immediately replacing the many familiar 12-volt devices employed in their cars.

Tesla’s new CyberTruck has entirely eliminated the traditional 12-volt low-voltage power network in favor of an all-48-volt configuration. While this is the likely end game for other automakers, those companies will want to take time as they migrate away from 12-volt devices that have proven reliability, reports Greg Green, director of automotive marketing for the company.

There are more than 100 12-volt devices in vehicles, whose replacements will each need testing, Green pointed out. “Replacing those with 48-volt devices requires a few thousand engineering hours and hundreds of thousands of dollars testing,” he said.

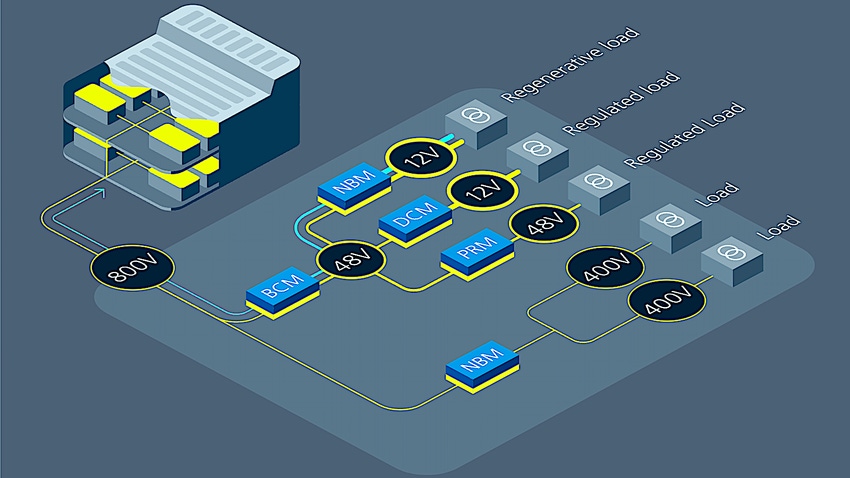

Vicor’s 48-volt zonal power modules provide automakers the ability to reduce the thickness of wiring in vehicles to 10-gauge while delivering high power to devices that need it. But they can also supply 12 volts to those legacy devices that carmakers want to retain while they test their eventual 48-volt replacements, Green said.

Some carmakers are addressing this situation by installing a 12-volt battery to run a separate 12-volt power network, but Vicor’s power modules can convert power from EVs’ high-voltage battery packs to provide that power without needing a separate battery. That saves 29 lbs. of weight in vehicles that are struggling with their mass because of the traction batteries.

“Our DC-DC conversion devices work so fast that we can create a virtual battery rather than having a 48-volt battery,” Green explained. “We’re able to convert power at 8 million amps per second, which is as fast or faster than most batteries transmitting power.”

Those who’ve been in the industry a while will recall that we were told a generation ago that cars would be switching to 48 volts, but that never happened. “In the early 2000s, we were told 48-volt was the next thing coming,” Green recalled.

But the inertia of 12-volt devices, with their low cost and proven reliability was too much for the 48-volt advocates to overcome, leaving the technology limited to isolated subsystems for engine stop/start systems, rear-wheel steering, and active suspension.

The shift to EVs means that power generation no longer depends on the familiar 12-volt alternator, making the shift more frictionless for automakers, Green noted. Now, there’s a high-voltage battery whose power needs to be converted to usable levels for the various devices on the vehicle. “When you have a high voltage battery that has to be stepped down, 48 volts is the natural first resting place,” he said.

That’s because it falls below the threshold of being injurious to people, should someone come in contact with the power, while providing good power level for those applications that need it.

For those applications that don’t, there isn’t much incentive for automakers to rush them to 48 volts, and Vicor’s ability to provide 12 volts in real time makes the idea of keeping some legacy systems at that level even more appealing.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)