Stellantis Partners with Saft on a Better EV Battery Architecture

This joint project consolidates existing technology to simplify EVs without new breakthroughs.

Rather than looking for the introduction of new technology such as solid-state batteries, Stellantis and French battery maker Saft are partnering to develop a new EV architecture for simplification and cost reduction.

Saft was the then-Chrysler Corporation’s battery partner on its early EPIC electric minivan project. Saft provided advanced nickel-metal hydride battery packs that gave the EPIC vans a range of 80-90 miles.

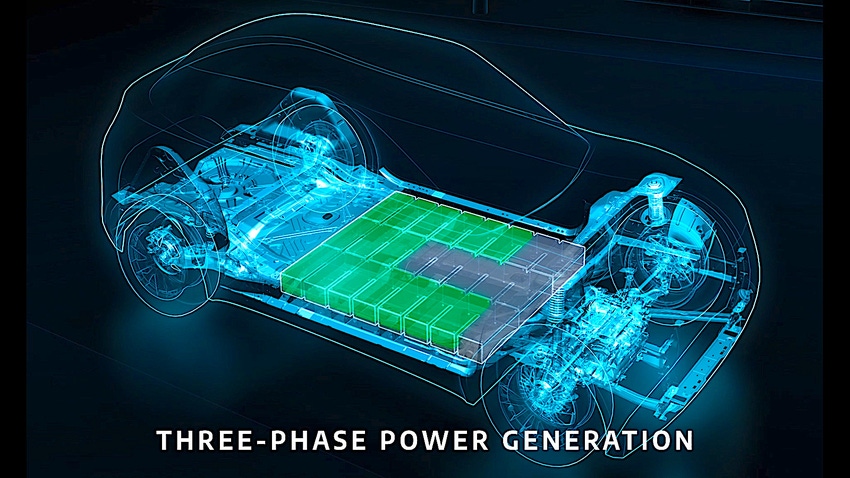

The Intelligent Battery Integrated System (IBIS) is a joint corporate and academic research project that integrates the electric charger and inverter functions into the lithium-ion battery modules by incorporating electronic conversion cards into those modules. This frees space in the vehicle and reduces total system cost.

The partners predict these consolidated battery modules will be employed in Stellantis production vehicles before 2030, and while other such long-term forecasts rely on the invention of new technologies, this plan relies on continued design, modeling, and simulation to perfect the new configuration. The next goal is to build a fully functional prototype vehicle for testing on development benches, test tracks, and eventually, on public roads.

“Our journey to electrification is fueled by innovation and research excellence that uses the latest technology to address the real needs of our EV customers such as range, roominess, and affordability while reducing carbon footprint by improving efficiency,” said Ned Curic, Stellantis Chief Engineering & Technology Officer. “This revolutionary battery system could mark a decisive step in Stellantis’ commitment to provide useful, easy, and advanced technology to all.”

In addition to Stellantis’s vehicles, Saft envisions employing this technology in its stationary energy storage products. “As pioneers in this cutting-edge field, our researchers are able to carry out research programs like IBIS over the long term,” remarked Cedric Duclos, Saft Chief Executive Officer. “We are delighted to have this collaboration with other recognized partners in this field of expertise, on this innovative project aimed at revolutionizing electric mobility and stationary energy storage.”

A team of 25 Stellantis and Saft engineers working at the CNRS (French National Center for Scientific Research), has already dedicated four years of work to the project, producing a demonstrator last year. The project validated many new technical concepts and let engineers master the control and operation of these systems.

Putting the power inverter and charger as close as possible to the lithium-ion battery cells, along with a sophisticated control system means that alternating current for the electric motor can be produced directly from the battery pack.

About the Author(s)

You May Also Like