Smoothly Stopping the Spin in SUVs

Eaton Corp. targets high-torque vehicles with new electronic limited slip differential.

March 16, 2017

Eaton Corp. has rolled out an electronic limited slip differential (eLSD) that promises to deliver a smoother form of stability control for pickup trucks, SUVs and other high-torque vehicles.

Known as IntelliTrac, the new product uses electronics to infinitely vary the bias torque between the wheels. “It elevates the safety performance of stability control beyond what throttle and brake interventions can do,” Rick Kukucka, director of product strategy for Eaton’s Driveline, Chassis and Control Group, told Design News. “And that’s important for automakers when they put in active driver assistance systems, such as adaptive cruise control and lanekeep systems.”

|

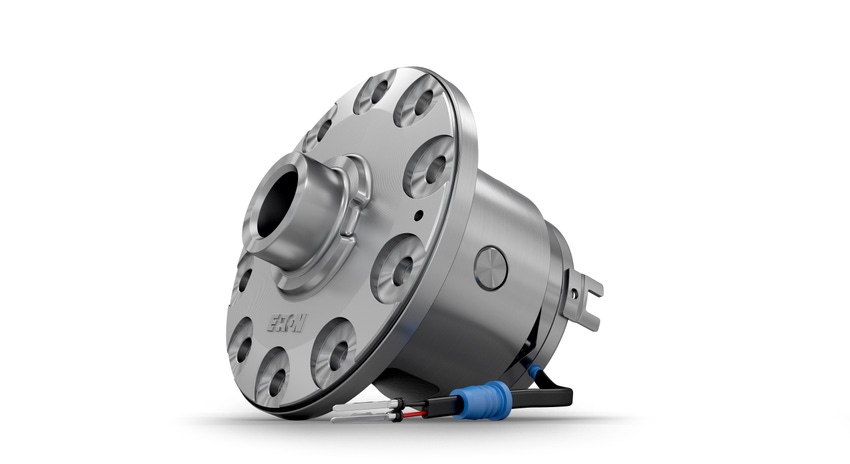

Eaton’s IntelliTrac is currently targeted at pickup trucks, SUVs and other high-torque vehicles. (Source: Eaton Corp.) |

The new eLSD product is unusual, and possibly unique, for the pickup and SUV segments, which typically require a bias torque (the torque difference between the inner and outer wheels) of greater than 3,000 N-m (2,200 lb-ft). Such high bias torques call for higher hydraulic pressures in the differential’s clutch pack and higher electrical current levels in its motor.

“There are other electronic limited slip differentials out there,” Kukucka said. “But this level of performance for vehicles of this size and torque hasn’t been done before.”

During instability events, the advantage of the new eLSD is smoothness. It accomplishes that by using data from common, existing sensors – steering angle sensor, wheel speed sensors, lateral and longitudinal “G” sensors, yaw acceleration sensors -- to determine if a vehicle is spinning. Then, it sends the correct amount of torque needed to smoothly stop the spin. It does so by changing the pressure in an infinitely variable fashion. That’s a departure from a conventional limited slip differential, which employs a couple of pre-set torque biases.

“What IntelliTrac can do is make those events so smooth that most of them are just transparent to the driver,” Kukucka told us.

Eaton says the new product will be especially important in vehicles that add automated driver assistance features, such as adaptive cruise control and lanekeeping. In such vehicles, an intervention from a conventional stability control system would likely be shocking to the driver.

Eaton engineers also expect IntelliTrac to be a benefit for full-frame vehicles used for towing applications, where lateral stability is highly valued.

Kukucka said there were three keys to enabling IntelliTrac for applications with bias torques above 3,000 N-m. First, he said, is the efficiency of its hydraulic control unit. Second is the use of a proprietary material that enhances clutch friction capability. And the third is the motor’s ability to operate at a 20A draw, instead of the more common 40A.

“With all the features on modern vehicles, current draw is becoming more critical,” he said. “The fact that we can deliver this with a 20A draw makes us unique.”

Ultimately, Eaton engineers say they plan to deploy a version of the technology for cars, as well as pickups and SUVs. For vehicle dynamics engineers, the advantage in either case is so-called “tunable bandwidth” – the ability to customize the differential’s operation across a wide variety of potential scenarios. “It gives them a pretty advanced tool, so they can tune the vehicle’s response to all kinds of handling conditions,” Kukucka said.

Driving the Future of Automotive Design. Federal mandates and environmental concerns have put fuel efficiency on the map for 2025. The automotive conference, held during Advanced Design & Manufacturing , March 29-30, 2017, in Cleveland, investigates lightweighting, the art and science that is lifting the pressure off automotive manufacturers. Learn about this trend's future and find out how new advances in lightweighting parts and materials can help you deliver the cars of the future. Register today!

Driving the Future of Automotive Design. Federal mandates and environmental concerns have put fuel efficiency on the map for 2025. The automotive conference, held during Advanced Design & Manufacturing , March 29-30, 2017, in Cleveland, investigates lightweighting, the art and science that is lifting the pressure off automotive manufacturers. Learn about this trend's future and find out how new advances in lightweighting parts and materials can help you deliver the cars of the future. Register today!

Senior technical editor Chuck Murray has been writing about technology for 33 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and autos.

About the Author(s)

You May Also Like