Red Bull Racing Employs Ansys Simulation to Help Win F1 Races

The whole suite of Ansys tools have helped Red Bull Racing create a virtual car that models the F1 championship-winning machine.

It is said that victory has a thousand fathers, so it is no surprise that after a record-breaking season for the Red Bull Formula 1 team some of the contributors to the team’s success would point out their contributions.

One of those is Ansys, Inc., the simulation software company whose products help companies reduce the need for physical testing. This is important because there are strict limits on how much physical testing F1 teams can do, so they rely heavily on computer simulation to minimize the necessary physical testing.

Red Bull Racing, the reigning Formula 1 champion, has used Ansys simulation technology since 2008 as a part of the team’s Innovation Partnership. The tools employed include:

Ansys CFD

Ansys HPC

Ansys Granta MI

Ansys LS-DYNA

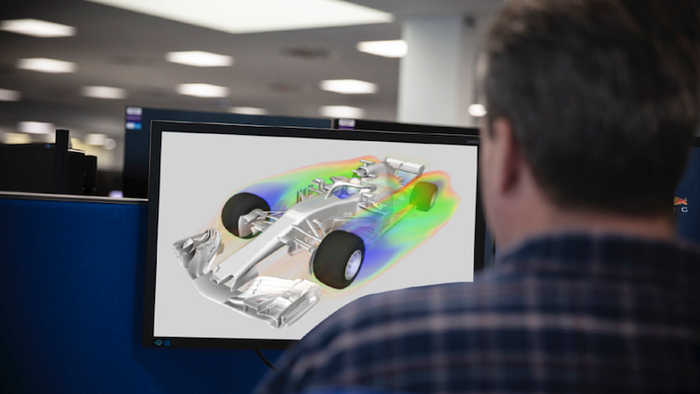

The team’s aerodynamics program, which is led by the best-known car designer in Formula 1, Adrian Newey, applies Ansys Fluent Meshing to generate models and create computation meshes.

Fluent CFD provides Red Bull with a virtual wind tunnel, but as with the real wind tunnel, the time that the team is permitted to employ this tool is restricted. CFD is not only important for refining the car’s aerodynamic drag and downforce, it is also necessary to ensure proper cooling of the car’s power unit, which contains both the turbocharged combustion V6 engine and the motor/generator, both of which need cooling airflow.

Additionally, F1 teams are prohibited from using wind tunnel models that are larger than 60 percent, so the accuracy of physical testing may not be as good in some situations as the simulation is.

“When we think about computation fluid dynamic simulation, the biggest job that it serves, probably, on the chassis side is how that exterior of the car is going to be shaped,” explained Zoe Chilton, head of strategy partnerships for Red Bull Racing in a YouTube interview posted by Ansys. “That’s not just individual components, the whole concept,” she continued. “How do we create downforce, how do we heavier as it goes faster, and how do we get the balance right between downforce and straight-line speed, because different circuits require different things from the car.”

Red Bull Racing's engineers are invited to participate in beta testing of Ansys software. ANSYS

The Ansys CFD software helps ensure that the aerodynamic team begins with a fundamental design that can be refined to achieve success. “The journey that we go on in that engineering process: we start off with a CAD model of the exterior shape of the car,” said Chilton. “We say, ‘This is a concept that we think will work,’ and different aerodynamicists on our team might have slight variations or ideas they might want to trial out.”

The huge volume of data involved with designing and building a Formula 1 car makes keeping track of current information a challenge, so Red Bull uses Ansys Granta MI to provide a comprehensive single source of accurate information for all the related materials.

“In an ever-expanding company, we need to make sure all of our employees are using a single source of truth for material database and material process information,” noted Greg Cooper, finite element analysis tools & methods leader. “We make sure they are used throughout the business: the designers doing the simulation work, all the way through to manufacturing that are building the parts, making the parts.”

This coordination continues once the car leaves the factory. “Even at the racetrack when we are doing repairs we still need to be using the same material information and making sure the processes are as the designer has designed,” Cooper said. “Using Ansys Granta MI, we can overcome these obstacles and make sure the right data is in the right place and is accessible by the right people at the right times.”

And while race cars are meant to go fast, not to crash, crashes do happen, so Red Bull employs Ansys LS-Dyna to perform virtual crash testing on the car to ensure the drivers’ safety. The team says that these virtual crash tests provide even more information than a physical crash test does.

Applying all these tools contributes to Red Bull Racing’s success, asserts Chilton. “When we then get to the track, we have higher confidence that the car we put on track will replicate the car we saw in the virtual wind tunnel,” she said. “And that’s what it's all about; making sure that your simulation car and your real car are as closely aligned in terms of data as possible.”

About the Author(s)

You May Also Like