Maserati Uses Aquafil Econyl Recycled Nylon

The Maserati Grecale Folgore EV underscores its green credentials by using recycled nylon in its upholstery.

At a Glance

- Nylon can be recycled infinitely

- Recycled nylon produces half the carbon emissions of petroleum-sourced nylon

- Recycling encourages recovery of ocean fishing nets

Maserati aims for its new all-electric version of its Grecale crossover SUV to be earth-friendly, thanks to its zero-emission electric drivetrain and the company is backing that effort with the use of recycled materials in the car’s cabin too.

This material is Econyl (pronounced “echo-neel”), which is produced by Italian nylon fiber maker Aquafil. The company employs 2,800 people working in 19 plants in eight countries, producing Nylon 6, Nylon 6.6, and Dryarn, in addition to Econyl.

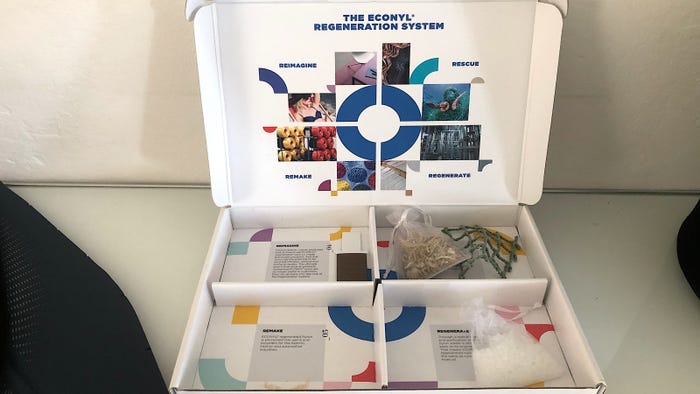

Econyl yarn (left) can be produced from a variety of sources. DAN CARNEY

Maserati uses Econyl for the fabric seat inserts in the Grecale Folgore EV, where it catches the eye with its unique, highly opaque surface that is reminiscent of the fabric used in bodysuits, combined with laser processing.

Econyl is a regenerated nylon made from recovered nylon waste such as fishing nets from the oceans and aquaculture, fabric scraps from mills, and carpets destined for landfill. What is important about recycled nylon is that the material is chemically recycled, rather than mechanically recycled by melting, as is the case with many plastics, explained Aquafil sustainability communications practitioner Martina Santoni during the Grecale Folgore media launch program in Italy.

Econyl regeneration exhibit at the Maserati Grecale media launch. DAN CARNEY

“Chemical recycling, versus mechanical recycling, makes it infinitely recyclable, she said. “It is the same quality as petroleum nylon. You can break down the connections between the molecules and put them back together.”

This like-new nylon production results in half as much carbon dioxide emissions as nylon made from petroleum sources, according to Aquafil. While the idea of repurposing old nylon to make new nylon seems so obviously beneficial that it is easy to wonder why this is only starting.

The answer to that question is: because it is hard! “We vastly underestimated the difficulty of this journey,” recalled Aquafil chairman and CEO Giulio Bonazzi on the company’s YouTube channel. “If we had known everything, I don’t know if we would have started this incredible journey.”

Or, as Santoni told me at the Maserati event, “The journey was complicated.��” For example, the nylon used in fishing nets is a perfect material for recycling. But when Aquafil started using it, there were immediate problems. It turns out that net makers coat the nylon with copper dioxide to keep seagrass from growing on the nets. “We had to invent a washing system to separate the [nylon] waste from the copper,” she said.

The material is appealing for other kinds of products beyond the automotive industry and is already in use by companies like Prada, Gucci, Dynafit mountain endurance sportswear, Coral Eyewear, and Mammut outerwear.

Ultimately, the goal is to close the circularity circle, with nylon reused in perpetuity, said Bonazzi. “The target is to not send anything to the landfill and not to take anything from our planet.”

About the Author(s)

You May Also Like