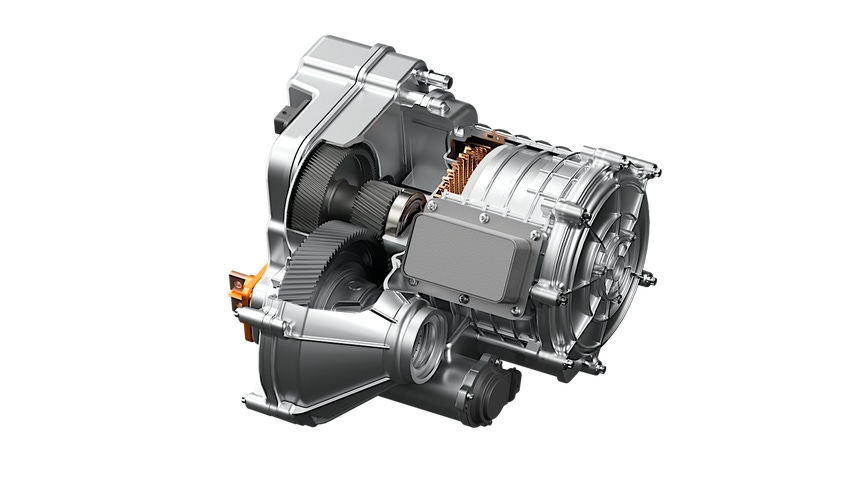

Magna's Next-Generation E-Motor: More Power, Less Mass

The new Magna EV motor is smaller, lighter, and reduces the use of problematic rare earth metals.

Magna has advanced the technology and design of its EV motor with significant upgrades to the motor design that improve its flexibility and reduce its size.

The new Magna eDrive is 20 percent lower in height than the outcome motor and weighs only 165 lbs. “The next-generation 800-volt eDrive solution sets new standards in efficiency, power-to-weight ratio, and torque density,” boasted Magna’s chief electrification engineer, Mike Dowsett. “It is a drop-in solution that incorporates several advanced technologies for significant reductions in weight and size, enhanced performance, extended driving range, and sustainability.”

The new motor achieves an overall efficiency of 93 percent compared to 91 percent for the previous design. It produces 3.33 kilowatts per kilogram, while the old motor made 2.0 kW/kg. Part of the increase comes from the new motor spinning at 20,000 rpm rather than the old motor’s 16,000 rpm limit. Peak power is 250 kW.

This new motor’s party trick is its ability to be installed in a conventional orientation or when rotated 90 degrees. This makes it suitable for installation in either front or rear locations without modification because the motor works while rotated to fit the space requirements of a front drive module.

Magna's Next-Generation eDrive on display at CES 2024. DAN CARNEY

This is due to a carefully designed oil cooling system that locates the pump so that it can pick up its oil supply from the bottom of the motor in either orientation. The motor’s active oil control system is crucial to its torque density because of the increased cooling requirements of the motor in high-torque situations, explained Dowsett. “For high-speed, low torque driving versus low-speed, high-torque, that’s when the magnets need a lot of cooling,” he said.

While the motor still has permanent magnets that require rare-earth metals whose supply is both fragile and fraught with ethical concerns, Magna has significantly reduced the amount of most of those materials and has completely eliminated use of terbium, Dowsett reported. While an eventual move to magnet-free induction motors is the company’s goal, “right now this is very good progress,” Dowsett said.

About the Author(s)

You May Also Like