Infineon MEMS Tire Pressure Monitor Q&A

Kim Lee, Infineon’s Senior Director of Systems Applications Engineering discusses the company’s MEMS technology’s application to tire pressure monitoring systems (TPMS).

Infineon has introduced its XENSIV SP49 tire pressure monitoring sensor, which integrates MEMS (micro-electromechanical systems) sensors and ASIC to provide advanced tire pressure monitoring systems. It features a 32-bit Arm M0+ core, flash memory and RAM, Low Power Monitoring (LPM), and optimized fast acceleration sensing. The SP49 is meant for intelligent tire functions such as on-tire auto-position sensing, tire inflation assistance, tire blowout detection, and load detection.

Handily for carmakers, the SP49 is a pin-to-pin replacement for its predecessor, Infineon's last-generation SP40 TPMS products. Thanks to its integrated microcontroller, sensors, and convenient peripherals, the SP49 requires only a few passive components to form a complete TPMS sensor unit. The device is designed for low power consumption, making it ideal for battery-powered applications.

Design News was curious about this application of MEMS technology to a TPMS, so we asked to speak with Kim Lee, the company’s Senior Director of Systems Applications Engineering for Sensors, Solutions, and IoT for the Americas.

MEMS seems like an unexpected technology for a TPS. How does it work?

Kim Lee: MEMS has mostly been used for TPMS in recent years. Piezoresistive technologies for TPMS use a MEMS process where the simple circuit model is four resistors placed on a silicon diaphragm that measures the result of strain or physical pressure applied upon them. This pressure causes a change in resistance that is being converted through a bridge circuit into an output voltage.

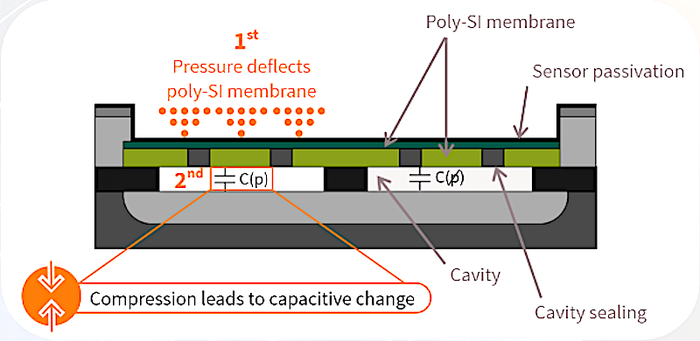

Infineon’s TPMS uses a capacitive technique which is better for accuracy and low power. The capacitive MEMS uses two parallel and electrically isolated conducting plates where the bottom plate is fixed while the top one is sensitive to pressure changes. When pressure is applied, the top plate (or membrane) bends and a capacitance change is created.

This variation in capacitance is then translated to an electrical signal where it can be read and conditioned by a microprocessor or ASIC. Most newer TPMS products such as Infineon’s SP40+ family incorporate the processing ASIC and more into a single IC package. This illustration below can provide a visual representation of the MEMS structure.

MEMS TPMS. INFINEON

What are the benefits of using MEMS?

Lee: MEMS technology has been predominantly used for direct pressure sensing in TPMS applications. Indirect techniques use wheel speed through the braking system to sense tire pressure. But even accelerometers and gyros are using MEMS technology.

The current TPMS technology uses MEMS capacitive pressure sensors that offer excellent long-term stability and better accuracy. These MEMS capacitive pressure sensors also have low power consumption since there is no DC current flowing through the sensor element due to its nature and therefore consume very low power in sensing pressure.

Can this system predict problems rather than just react to them?

Lee: The TPMS monitors the pressure sensor and feeds the information to the central processing unit to display the tire pressure on the driver’s instrument panel. Some cars just have an LED light indicating low tire pressure.

This is a type of prediction for low tire pressure warning and alerting the driver to address it by checking the tire or adding more air. More sophisticated algorithms can be used to determine the rate of pressure change and determine if the air pressure delta is a slow change (slow leak) which may be okay to drive another 50 miles before addressing, or a fast enough change where any further driving will cause a potential accident. The algorithm would reside in the processing unit that takes the TPMS data, determines predictive behaviors, and suggests specific actions.

How can the load detection be employed by truck manufacturers to provide drivers important information?

Lee: Load detection through TPMS could be possible by monitoring the tire pressure during an unloaded truck, and then computing the delta on the tire pressure when the truck is loaded with cargo. The weight of the truck can be correlated to the air tire pressure to provide driver information. A separate MEMS pressure sensor can be applied to the system that detects the weight of the truck itself outside the TPMS system as a separate way of measuring load weight.

What are the potential future capabilities of this technology?

Lee: MEMS technology is used in many applications such as microphones, gyrometers, accelerometers, ultrasonic sensors (same as a microphone except using the >40kHz band), magnetic sensors, and gas sensors. Infineon incorporates MEMS technology in many of our sensor products that you see on our website including our TPMS sensors.

About the Author(s)

You May Also Like