Changes in CAD Functionality Keep Coming

Given a product as mature as CAD, it’s surprising how much new functionality is still getting added to the old war horse.

August 17, 2016

In just the last year, CAD programs are glowing with the luster of shiny new functionality. 3D printing has revamped the whole notion of what constitutes shape. 3D PDFs are changing the way drafts are shared, and new tools guide design engineers to create objects that are manufacturing friendly. And smart storage systems are in place now to let you know the archive contains a pre-designed product that is very similar to the image you’re creating on your screen.

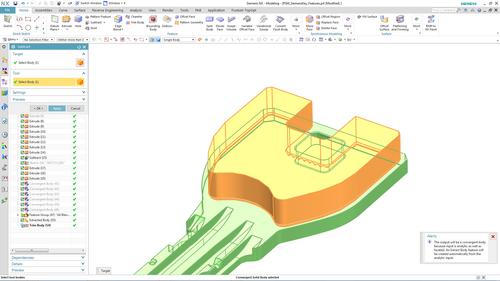

Convergent modeling technology for medical implants shows a tool body trimmed with convergent bitmap.

(Source: Siemens PLM)

2D Napkin Drawings Still Popular

The 2D drawing of a product is often the starting place for an idea. Yet the idea will have to be taken into 3D for full development. CAD companies know this, so many have created a shortcut to take the 2D drawing into 3D without a go-to-scratch redesign. “A lot of customers do initial concepts in 2D because it’s simpler and easier. The 2D drawing often gets completely rebuilt in 3D. It may have to be completely redesigned, especially with gear boxes and gears. We’ve built a bunch of capabilities to move the drawing from concept drawing into 3D design,” said Brian Thompson, SVP for CAD at PTC. “Now you can have a 2D drawing that is completely reusable in 3D. You can continue to use the 2D and still move it to 3D.”

3D Shapes of Things to Come

3D printing has forced CAD to recognize shapes that previously were not considered viable. The additive manufacturing process has thrown the CAD system for a loop. So CAD had to be retaught what a viable shape is. “People are looking at new shapes and new substances that puts extra demand on CAD. You get the chance to do different shapes because of 3D printing. Modeling those 3D printing shapes with traditional tools isn’t easy. The existing tools are built with an understanding of traditional geometry,” said Paul Brown, director of project management at Siemens PLM. “The lattice shapes you can get from 3D printing are really hard to define with traditional solid geometry. The CAD system forces me to make it into a solid. That’s just wrong.”

3D PDFs Gain in Popularity

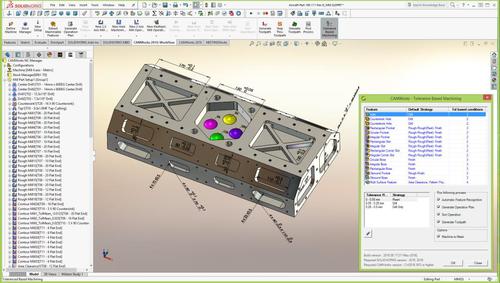

Another recent trend in CAD is the ability to send a copy of a 3D drawing in a PDF file that can be opened by anyone. All of the details of the 3D drawing come across intact. “You can output a PDF that anyone can open. You open that up and you get a drawing. If you still want to put it on paper, you can print out the views. The great value of a 3D PDF is it’s just like your 3D model. When you look at the dimension or tolerances, when you click on it highlights, it’s in 3D,” said Craig Therrien, senior product manager at Dassault Systèmes’ SolidWorks. “When you look at a 2D drawing you don’t know if it goes to all dimensions. The 3D PDF elevates that. If you click on a feature, the two faces highlight. You can rotate it or see inside. A much better way of looking at an object.”

SolidWorks 3D drawing.

(Source: SolidWorks)

Put Everything in the CAD Drawing

The CAD model is also becoming the single instance of the truth for the product. All relevant data can be attached to the CAD file instead of having it collected as separate files. “Everything you need for the product is in the CAD file, all the notes, tolerances, even data on simulation results, costing information,” said Therrien. “All the things you would usually put in separate files – the visualization, early renderings, inspection data – they’re all in the CAD file. The goal is to add intelligence to the 3D model.”

Machines are Learning How to Design

Machine learning is becoming a facet of CAD design. The CAD system will examine work that the design engineer is performing and see ways to shorten the work by using existing drawings. “Say you have a vault with all of the data from the last few years. As you design, the CAD system learns from the data management platform. It will look at what you’re doing, and it will begin to figure out what you’re about to create,” said Stephen Hooper, senior director at Autodesk. “It will try to assist you by making predictive suggestions to help you design it faster or help you to stop designing something you’ve designed in the past. It will say, ‘Hey, it looks like you’re designing a bracket, do you know you’ve designed some of these before?’ It’s a real leap forward.”

READ RELATED ARTICLES ON DESIGN NEWS:

Design automation -- which sounds like an oxymoron -- is also getting deployed in the design process. “You can turn CAD models into knowledge assets by developing configurators that effect productivity. We’ve seen our clients use these tools to reach a point of efficiency that impacts design-to-market and engineer-to-order performance like never before,” said Carl Smith, director of manufacturing services at IMAGINiT Technologies. “Autodesk Inventor Simulation offers a look at how processing power can be leveraged to suggest design decisions. Right now the tool is focused on weight reduction based on factors of safety criteria, but I am excited to see where it goes with respect to other design decisions.”

CAD Is Built for Collaboration

Sharing data files is also becoming part of the new world of CAD. If the CAD drawing also contains data related to regulations or BOM lists, it needs to be easily shared with people outside the design process. “It has become mandatory that design data -- not just CAD files, but all associated information -- be readily available to those who need it with minimal impact to the actual design process. Companies need an efficient and effective way to share data in an automated and secure environment,” said Smith. “Companies are realizing that emails and spreadsheets are not the most productive way to facilitate processes like new product introduction, company-wide change management, or RFQ procedures.”

The Customer Is in on CAD Advances

So how do CAD producers figure out what their customers need? Many create sharing forums to find out the issues their customers have with CAD systems or with design challenges in general. CAD providers understand they can’t take all their direction from customers. After all, Henry Ford once said, “If I asked people what they wanted, they would have said faster horses.” Even so, customer feedback can be critical. “We started as a cloud-based subscription so we can talk about the future of our products. We wanted to be upfront with our customers, so we included our product roadmap in our blog. That’s a bit of a change for us since we wouldn’t ordinarily announce what we’re going to do over the next 12 months,” said Hooper from Autodesk. “We asked whether our direction was a good idea or a bad idea. We asked what they liked or didn’t like about it. People who have subscribed to a software product appreciate that. They want to know you value their opinion.”

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)