A Preview of Rivian’s Dual-Motor EVs

EV startup Rivian has developed its own lower-cost in-house electric motors for its acclaimed EV pickup and SUV.

Design News has loved Rivian’s vehicles since our introduction to the R1T electric pickup truck nearly two years ago.

Consumers have loved the R1T and its SUV sibling, the R1S, too, with demand that Rivian has struggled to meet. Along the way, Rivian has raised prices, from the original starting price of $67,000 to today’s $95,000.

Those vehicles employ Rivian’s Quad-Motor design, which uses a quartet of Bosch-supplied motors that each drive one of the R1T’s or R1S’s wheels. This gives the vehicle the ability to precisely control wheel speed, so it has amazing off-road capability and on-road handling.

Munro Live Teardown Reveals Rivian Battery Design and Construction

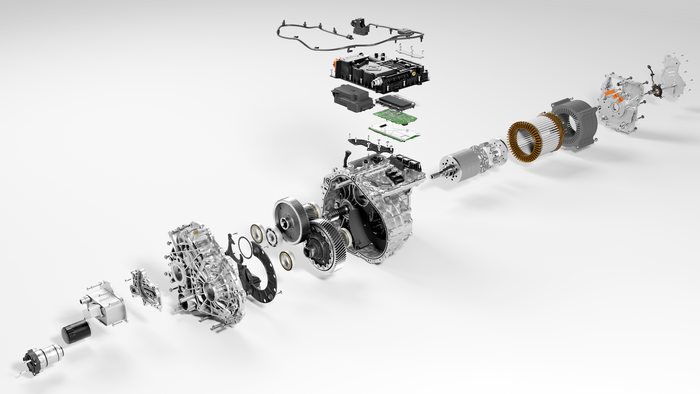

But those capabilities exceed the needs of most drivers, so in a bid to provide some price relief, Rivian has developed its own in-house electric drivetrain, called the Enduro. This is the same drivetrain used in Rivian’s electric parcel delivery vans that it has been building for Amazon.

The new Dual-Motor Rivian R1S and R1T use one of those Enduro drivetrains at the front and another at the rear and they use a brake-controlled system to manage traction and wheel speed, much like a combustion vehicle typically does. This has brought starting prices back down closer to the original levels, though now with a less capable vehicle.

The Dual-Motor models’ drivetrains are rated at 533 horsepower and 610 lb.-ft. in standard configuration, which accelerates them to 60 mph in 4.5 seconds. For an extra $5,000, buyers can upgrade to the Performance Dual-Motor specification and enjoy 665 hp. and 829 lb.-ft., delivering 0-60 mph acceleration in 3.5 seconds.

The difference between these vehicles is entirely in the software, leaving the possibility that base model buyers can later upgrade to Performance specifications by buying a software upgrade. Such an after-the-fact upgrade is not currently offered, but Rivian executives concede that it is an obvious future possibility.

The original Quad-Motor vehicles are quicker and thirstier, with 3.0-second acceleration and a driving range of slightly more than 320 miles. In back-to-back drives, the difference between the Dual-Motor and the Quad-Motor models is barely discernable when driving on pavement. The Quad-Motor has a noticeably stronger kick when accelerating from medium speeds, but the difference was only apparent because the drives were back-to-back.

For off-road driving, the difference is more apparent. As when I drove the Quad-Motor R1T in Breckenridge, Colo., the original Rivian scrambles effortlessly over obstacles and up hills. The Dual-Motor makes the same ascent, but in a manner more like a combustion-powered 4x4. The traction control system is audibly at work, squeezing the brake on wheels without traction to drive power to those that have grip.

Both versions of the truck climbed the hill Rivian has built behind its Normal, Illinois factory for off-road demonstrations and testing, but only the Dual-Motor vehicle seemed to have to work to reach the summit.

The front and rear drivetrains in the Dual-Motor vehicles are very similar, but not identical. The gearing provides more torque for the rear axle, contributing to the ability to send as much as 70 percent of the torque to the rear when needed.

But because the front drivetrain is the primary driver in normal conditions, Rivian employs silicon carbide power electronics on the front axle of the Dual-Motor. This contributes a 3.5 percent improvement in the vehicle’s driving range, according to Senior Director for Electric Power Conversion, Silva Hiti. Quad-Motor Rivians get silicon carbide front and rear. The material is valued for its efficiency handling high current, but it does add hundreds of dollars of cost for Rivian compared to the conventional silicon semiconductor power electronic modules. The company expects to move toward 100 percent use of silicon carbide over time as the cost declines, execs said.

The new, more affordable Dual-Motor base prices of $73,000 for the pickup and $78,000 for the SUV apply to the Standard battery pack, which won’t be available until next year. The current base pack is called the Large battery and there is a bigger one called the Max for the longest driving range.

The Large pack, which has a driving range of 352 miles, and the Max pack, which has a range of 410 miles for the R1T and 390 miles for the R1S, both employ Nickel-Manganese-Cobalt (NMC) battery chemistry. The Max pack has the same number of cells as the Large pack, but it uses cells with a more advanced, and expensive, version of that technology.

The Standard pack uses the same less expensive cobalt-free Lithium Iron Phosphate (LFP) batteries as Rivian installs in the Electric Delivery Van it builds for Amazon. In the R1S that battery pack will deliver about 260 miles of driving range, with an extra ten miles of range predicted for the R1T.

The maximum driving ranges are achieved on 21-inch wheels, with the available 22-inch wheels trimming about ten miles from the driving range because of their added mass and aerodynamic drag. EVs typically drive further on smaller wheels, but Rivian’s available 20-inch wheels have a much shorter driving range of 307 miles with the Large battery pack because those wheels are used with off-road tires that have more rolling resistance.

My visit to Rivian’s factory for the Dual-Motor test drive also provided the opportunity to tour the plant. Seeing the vehicles coming off the assembly line provided confidence that the company’s forecast of producing 52,000 vehicles this year seems achievable.

Rivian bought the former Mitsubishi plant in 2017 for $16.5 million and thanks to a 620,000-foot expansion for Enduro electric motor production, has grown the facility to more than 4 million square feet. More than 7,000 workers are running the plant for three shifts with the help of more than 1,000 industrial robots.

The plant's visible productivity gives hope that impatient Rivian customers won't have to wait much longer for delivery of their vehicles. And Design News is looking forward to the opportunity to spend more time with a Dual-Motor R1S for some real-world testing soon.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)