Ongoing Manufacturing Challenges: Uptime, Materials, and Workers

With the pandemic mostly behind us, manufacturers continue to struggle with issues of equipment maintenance, materials management, and staffing.

June 21, 2023

Despite interest-rate hikes, the economy is still heating up. This offers encouraging opportunities for manufacturers. Yet hitches remain. Equipment needs to operate predictably and materials need to flow consistently across supply chains that remain too long. Plus, a decade-long worker shortage in manufacturing isn’t helping matters.

Here are three areas that need improvement for manufacturers to operate effectively – and competitively – during a period of growing demand:

Leveraging automation and predictive analytics to maintain product quality in a time where speed is of the essence

Technology’s role in balancing material availability during shifting demand

Working to meet the challenge of an ongoing worker shortage in manufacturing

We caught up with Gustavo Sepulveda robotics and automation business head at Panasonic Connect to see how these three challenges can be addressed in manufacturing.

Predictive Maintenance

Design News: How are predictive and preventative maintenance technologies helping to reduce downtime?

Gustavo Sepulveda: Machine line downtime is extremely expensive for manufacturers. It can cause delays throughout the entire supply chain -- and with supply chain disruption top of mind for business leaders over the past few years, predictive and preventative approaches to manufacturing are priorities. Maintenance and support features are now of the utmost importance when looking for new technology to back manufacturing operations. Taking a more proactive approach to maintenance and support is what manufacturers seek.

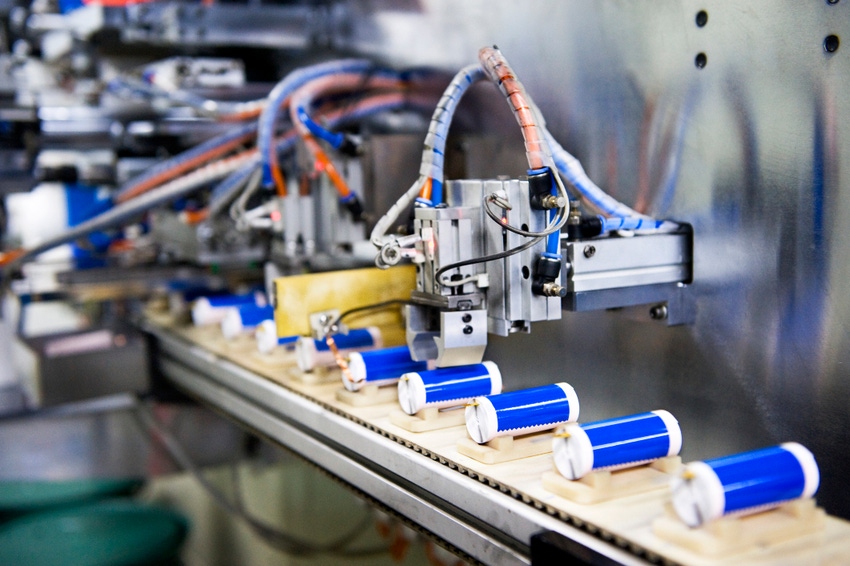

Understanding when a machine may fail, when a machine’s health is expected to suffer, or when its performance isn’t matching expectations – these are all examples of the need to utilize more preventative models where automated intelligence can start to identify outliers and flag potential issues before they arise. This is one variable that manufacturing is trying to remove from the supply chain with the help of technology. Being able to plan for, work around, and communicate required downtime is where we are headed— which is a win for all touchpoints along a supply chain.

Materials Management

DN: What are some of the strategies for managing materials during shifting demand and ongoing variability?

Gustavo Sepulveda: The past few years forced people to take stock of and better understand the manufacturing industry. What resulted was a heightened awareness of just how many millions of dollars of raw material make its way through facilities, how many different manufacturing lines can be run, and how precise material management and material control must be to reliably produce. Whether raw material, working product, or finished product, the material is constantly running through facilities.

One misplaced item can create a multitude of problems throughout a facility. Emerging software and smarter machines are in demand to solve this problem, detecting material issues on the line, or giving greater visibility in material flow to catch problems before the process starts. Visibility is key. And, we will see a greater integration between new hardware, software, and existing manufacturing equipment to bring advanced prevention of these kinds of mistakes.

The Persistent Worker Shortage

DN: How do you address the challenges of the worker shortage?

The answer is technology. People are joining the manufacturing industry – or are expressing interest in doing so at the onset of their careers. There’s a lot of positive conversation about opportunities in our industry for several reasons. We see the growth of manufacturing in North America. Emphasis is being put on the industry with the likes of the Chips Act and now the PCB Act.

Students and emerging professionals are seeing this dedication to innovation throughout the industry. Manufacturing is becoming more technological, more advanced with IoT, and more complex with computer science, and these qualities are attracting digitally-native or digitally-inclined talent. Yes, you still need deep manufacturing experience, but technology acumen will continue to rise in importance within our industry, which is good news for emerging talent.

About the Author(s)

You May Also Like