How to Build a Better Control Panel

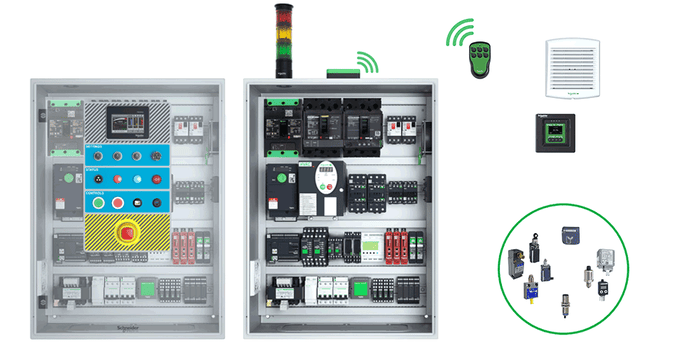

As companies move more of their industrial operations into automation, control panels are becoming more complex.

August 21, 2020

As companies move more of their industrial operations into automation, control panels are becoming more complex. Manufacturers are adding more sophisticated machines, they’re overlaying predictive maintenance sensors and systems to ensure the smooth operations of the equipment, and they’re adding software, machines, and data tools that come from different suppliers. This increases complexity as users work to integrate disparate technology.

Designing automation systems is a tricky business. Manufacturers are moving away from the days when they would choose one automation supplier and that supplier would work with an integrator to make sure everything fit and worked successfully. Increasingly, manufacturers are looking for automation components and software from a variety of suppliers. Often, they work with a system integrator to make sure everything functions in harmony. Another alternative is to work with a components and automation distributor that provides a hub where design engineers to ascertaining the compatibility of system components.

To get a better idea of the essentials of building a better control panel, we spoke with Jim Davis, the director of advanced solutions and technical support at Allied Electronics & Automation, and Shannon Chiles, control panels business development manager at Schneider Electric also weighed in..

Design News: What are the constraints (difficulties) in creating an industrial control panel?

Jim Davis: In terms of laying out industrial control panels, I find that wiring plays an absolutely critical role in effective design and construction. First, you have to separate the power and control wiring so there’s less of a chance that electrical noise could affect control signals. Second, you need to separate field wiring from internal wiring by placing terminal strips so that there are wire ducts for each – and that means selecting the proper size wire ducts so you conserve as much space in the enclosure as possible. Finally, you must make sure to properly ground the panel and devices, by including a row of ground terminals in the panel.

Design News: How have these difficulties been addressed in the past?

Jim Davis: Mostly manually or with design tools by panel builders based on which components they know well or have used in the past. This is convenient, but it can sometimes be limiting in terms of what components can be used and what their capabilities are.

Design News: Schneider Electric and Allied Electronics & Automation recently created what they are calling a "hub" for the building of control panels. How does this hub help?

Jim Davis: The goal of the Schneider/Allied digital hub is to provide a central location for technical guides, as well as product information for a wide range of components that can be selected by panel builders. It also makes it easier to find new control panel components that might save space or provide a capability the builder didn’t previously know about.

Design News: What are some of the primary underlying challenges with building industrial control panels?

Shannon Chiles: The primary challenge for industrial control panel builders can be summed up in one word: efficiency. In an increasingly competitive market, efficient product selection, efficient product procurement, and efficient integrated application are extremely important to a control panel builder’s success.

Design News: Is increasing complexity part of the issue? If so, how?

Shannon Chiles: Increasing complexity is constant in industrial control. The control panel builder’s clients are always looking for better technology that works well together. This could be anything from remote monitoring to wireless technology to access to cloud analytics. Additionally, UL standards are constantly changing. Control panel builders need to understand these changes and how they apply to the panels they build.

Rob Spiegel has covered automation and control for 19 years, 17 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cybersecurity. For 10 years, he was the owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)