Can Advanced Tech Improve Manufacturing Productivity?

Sometimes yes, sometimes no. The possibilities and pitfalls of manufacturing technology will hit the spotlight in a session at IME West.

January 19, 2024

At a Glance

- Manufacturing technology

- Productivity difficulties

- Industrial transformation

Industrial manufacturing has gone through four major revolutions since the first mechanical loom in 1784. We’ve seen the introduction of mechanical systems powered by water and steam on through to the latest Industry 4.0 cyber-physical systems.

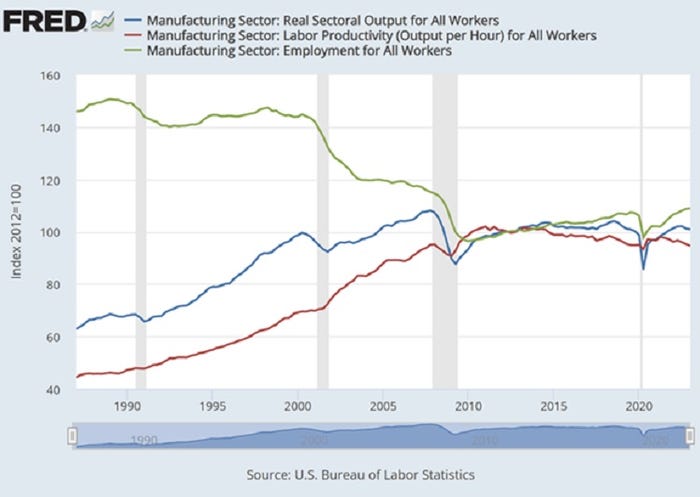

LNS Research, a group that helps industrial companies transform their organizations, has revealed research showing that manufacturing companies are investing heavily in industrial transformation. Yet those companies need to invest correctly to achieve significant results. The paradox is that, even with major innovation and investments, labor productivity has stagnated since the Great Recession.

Niels Andersen, principal research analyst at Factory of the Future at LNS Research, will cover the difficulties in manufacturing in his session, Manufacturing in the USA: Productivity Plateaus, Paradoxes, and Proven Solutions on Wednesday, February 7 at 1:15 pm at IME West in Anaheim. “In this session, we will explore the reasons for the stagnation and eight proven solutions for transformation,” said Andersen.

We caught up with Andersen to get further information on the challenges manufacturers are facing.

You mention in the program blurb that “manufacturing companies are investing heavily in industrial transformation.” What type of transformation does that involve? Digitalization? The addition of robotics? Predictive maintenance?

Niels Andersen: We define industrial transformation as both a sub-set and a super-set of digital transformation.

It is a sub-set as it is focused on industrial operations (the creation and delivery of the products).

It is a superset as it is not just technology. It is rooted in business objectives and includes strategy, initiatives, operational architecture, change management, organizations, etc.

Has that investment paid off for manufacturers?

Niels Andersen: Both yes and no. Most fail, but the ones who succeed have significant results. Some companies have bucked the negative trends and succeeded.

You also mention that “investments, labor productivity has stagnated.” What is involved in labor productivity? Robotics?

Niels Andersen: The basics of labor productivity are as defined by US Bureau of Labor Statistics as Output per Hour.

Bureau of Labor Statistics

Why has this productivity in manufacturing stagnated?

Niels Andersen: That is the billion-dollar question. We see multiple reasons, and we are actively researching this as we speak. Some that are clear are:

Change in the workforce. We have experienced the “Great Goodbye” and lost decades of deep experience that kept manufacturing out of the gutter.

There is the perception that manufacturing is not good work – low self-esteem and not strategic.

We never let a good crisis go to waste – The recent recessions have caused cuts in the workforce that have had unexpected results, including stagnated productivity.

We’re experiencing an unpredictable and unmanageable supply and demand.

The supply chain is complicated by outsourcing, off-shoring, and cost cutting.

You mention that you have “eight proven solutions for transformation.” Without revealing the core of your presentation, could you give us an idea of the nature of these solutions?

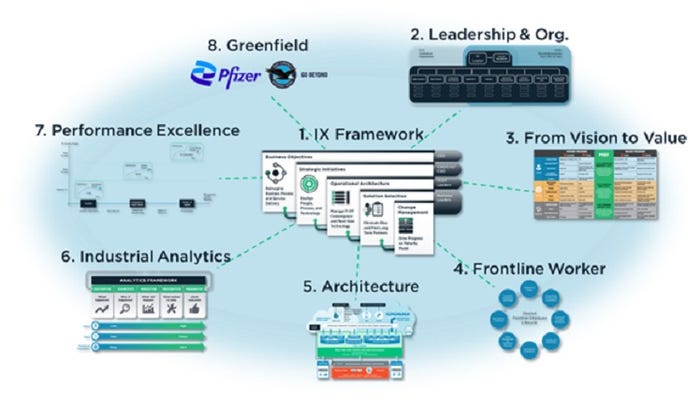

Niels Andersen: Here they are. I’ll cover them in more depth during the presentation at IME West.

LNS Research

Industrial transformation framework (IX)

Excellent leadership and organization

Clarity from vision to value

Focus on the frontline worker

Pay attention to your architecture

About the Author(s)

You May Also Like