4 Types of Surface Finishes and When to Use Them

Understanding surface finishes is critical to manufacturing efficiency.

June 14, 2021

José Luis Martín Cara

Surface finishing is a vital part of many manufacturing projects. How the exterior surfaces of a part or component are made ready for use is important to the manufacturing process. Once a surface is ‘finished’, it will not usually be subjected to any other processing.

There are several different types of surface finishes. Understanding them allows you to improve manufacturing efficiency while also reducing the need to invest resources into a trial and error approach to picking the right one.

Here are just a few of the common finishes you need to understand, and here are the benefits they bring to the table.

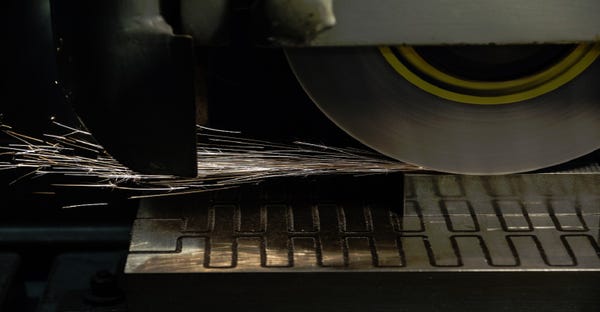

Grinding and Lapping

When a used CNC mill is put to work on the shaping of raw material into a completed part, the tooling will invariably leave marks on the surface which may need to be removed when extremely tight tolerances are required.

Removing these imperfections and creating a smoother surface finish on metal parts can be done by grinding or lapping, both of which rely on abrasion to get the job done.

Grinding and lapping can be used on a variety of metals such as mild steels and alloys as well as brass and iron. The main difference between grinding and lapping is that lapping involves the use of fluid as the medium to contain the abrasive grains that are removed from the surface.

These processes can be used to make aerospace and automotive parts, as well as more generally in manufacturing where a smooth, burr-free finish is preferred for aesthetics and safety.

Coating

There are several sub-categories of surface finishes that fall under the broader umbrella of coatings. The most common is the inexpensive application of commercial paints. Paints can vary in their capabilities. Some simply add a splash of color, while others help to actively prevent corrosion from forming on the surface of the parts they coat.

Powder coating is a more modern equivalent to painting. It makes use of an electrostatic charge to attract particles of powder to a part to cover the surface evenly with minimal waste. It is then cured through heat treatment or the application of ultraviolet rays. This is a quick and efficient option for finishing the surface of vehicle body panels, bike frames, other metallic components.

Electroplating

Electroplating is widely popular as a means of improving the durability and reducing the corrosion susceptibility of metals as well as giving metals an eye-catching look. The process has been around for more than two centuries.

It works by submerging the part to be plated in a bath of solution that contains ions of the intended metal coating. DC power is applied, causing the ions to be attracted to the metal part and leaving it with a new layer of material over all exposed surfaces.

Electroplating is used to make parts look good and last longer, but it can also be used as a means for maintaining and repairing worn components. Electroplating can be used to add precious metals to more affordable ones while making jewelry. It can be used to create printed circuit boards.

Blasting

Blasting is an abrasive form of surface finishing. The process involves the firing of small particles of material – including sand and steel shot – at a larger workpiece at high pressure. The impact of the particles abrades the surface, removing loose detritus, ironing out imperfections, and leaving a matte finish.

Blasting is often applied to remove rust, paint, and other coatings from older components and tools. It can also be used in the production of new components.

A combination of different surface finishing techniques is often used to create a product. It is a good idea to investigate the details of each surface finishing process to determine which ones are best suited to your individual needs.

José Luis Martín Cara is a writer with Revelation Machinery.

You May Also Like