Slippery Material System Can Start, Stop Liquids

April 17, 2013

A new material system invented by researchers at Harvard's Wyss Institute for Biologically Inspired Engineering is continuously "tunable" for transparency and wettability: it repels water or oil to a greater or lesser degree as it becomes more or less transparent. The research team envisions a wide range of tunable, multifunctional adaptive materials that can be designed for applications in textiles, optical systems, and fuel transport.

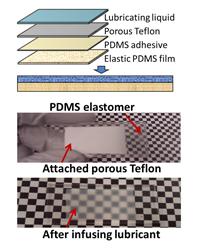

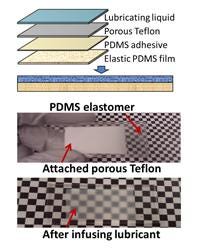

In the system, described in an article (purchase or subscription only) in Nature Materials, a liquid film both coats and is infused in a substrate made of an elastic, nanoporous material. When the substrate changes shape, for example, by stretching or squeezing it, the size of its pores changes. This, in turn, changes the shape of the liquid surface material. The surface and substrate materials can be adapted to particular applications.

In the proof-of-principle experiments described in the article, the team used porous Teflon mounted on elastic polydimethylsiloxane (PDMS), a polymer, for the substrate and the fluid was Dupont's Krytox 103, a perfluoropolyether (PFPE), lead author Xi Yao, postdoctoral fellow at Harvard's School of Engineering and Applied Sciences (SEAS) and at the Wyss Institute, wrote in an email to Design News. Krytox is a family of synthetic lubricants for extreme environments and harsh conditions, such as extreme temperatures, humidity, and reactive chemicals. Typical commercial and industrial uses include lubricants for valves, bearings, motors, and machinery in aerospace, automotive, industrial, and vacuum pump applications.

"Although we used these materials to demonstrate the basic concepts, the requirements are quite flexible," Yao told us. "The substrate can be any porous or textured elastic material, chosen to respond to a variety of stimuli. The liquid can also be varied to suit the application, for example, biocompatibility."

Being able to use a liquid as the top surface material is what allows that surface to be continuously tunable, instead of requiring a specific number of separate, discrete step changes. When the sandwiched material is stretched or bent, the liquid flows within the substrate's pores, which roughens the surface by giving it a more varied topography. This makes it possible to precisely control how fast and where drops of oil or water move.

The drops can even be stopped and started while rolling down a vertical surface, which you can see in the first two videos on this page. Previously, most materials developed to adapt dynamically to changing conditions could only change a single property, and those changes were limited to two states: on or off, for example, either hydrophobic or hydrophilic. This material system can be stimulated via mechanical means in very fine gradations to change both wettability and transparency.

A material system that dynamically responds to those changes in wettability and transparency might be used for a tent that is transparent and repels water during low-light, rainy conditions, or shifts to opaque when the sun is out and there's no rain. Materials with other characteristics such as adhesive or anti-fouling can be fine-tuned to respond to changes in surface roughness. Applications might therefore include oil and gas pipelines that can change the rate of flow depending on external weather conditions and how much fuel is pouring through them. The porous elastic solid could be designed to respond to a number of environmental stimuli, such as light, temperature, pressure, chemicals, or magnetic or electrical fields.

The material system is the next-generation version of the Slippery Liquid-Infused Porous Surfaces (SLIPS) material platform designed by the senior member of the current research team, Joanna Aizenberg, professor of materials science at Harvard's SEAS and a Wyss Institute core faculty member. Other team members that developed the new material system are L. Mahadevan, professor of applied mathematics at SEAS, professor of organismic and evolutionary biology and professor of physics at Harvard, and a Wyss Institute core faculty member; Yuhang Hu, a Wyss Institute and SEAS postdoctoral fellow; Alison Grinthal, SEAS staff scientist; and Tak-Sing Wong, assistant professor of mechanical engineering at The Pennsylvania State University. Research was supported by the Air Force Office of Scientific Research, the Office of Naval Research, and the Wyss Institute.

Related posts:

About the Author(s)

You May Also Like