Mechatronics Improves Design & Operation of Medical Devices

September 12, 2013

Mechatronics date all the way back to 1969, when the Japanese firm Yaskawa coined this term blending the words "mechanical" and "electronics." Steady advancements in technology -- especially the software that drives the system and wireless connectivity that links it to other computers -- have vastly expanded its use.

Today, a major focus area for mechatronics is medical devices. By integrating mechanical and electrical hardware with software processes, device designers can deliver highly sophisticated functionality. The beauty of mechatronics lies in flexibility, enabling its use in a huge and growing range of applications, from positioning systems in hospital beds to robotic surgical devices. Classic examples of mechatronic devices include the pacemaker and defibrillator, as well as the active ankle-foot orthosis featuring computer-controlled actuators to improve gait.

Newer devices include advanced active prosthetic limbs, such as prosthetic hands and fingers that let users grasp and maneuver objects. In the surgical area, the highly sophisticated da Vinci system from Intuitive Surgical allows the surgeon to perform minimally invasive procedures through tiny incisions by manipulating several robotic arms while viewing the site remotely using 3D vision technology. Mechatronics translates the surgeon's hand movements into the actions of the robotic arms. Another example is a new type of endoscopic procedure in which the patient ingests a small capsule containing a tiny camera that wirelessly transmits 360-degree views of the body to a memory card in a vest worn by the patient. This allows physicians to visualize the small bowel, colon, or esophagus remotely without a traditional endoscope.

Trends in mechatronics

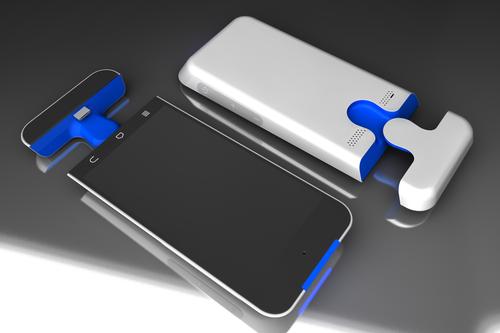

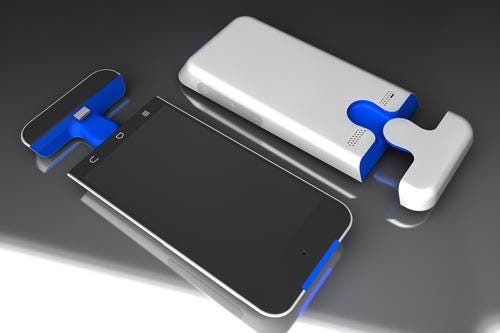

As evidenced by some of the above examples, one major healthcare trend affecting mechatronics technology is miniaturization. Ever smaller instruments and devices are being developed to enable less invasive surgical techniques that allow faster recovery. The use of microactuators and microsensors is driving the development of tiny mechatronics designs for:

Instruments for flow cytometry, DNA identification and sequencing, and pathogen detection

Medical imaging using small, precise modules for lens control and laser tuning

Implantable devices that can be dynamically adjusted in situ

Mobile miniature robots

Micropumps and auto-injectors for drug delivery products

Handheld diagnostics for use at the point of care

Another important trend is the increased emphasis on patient comfort and device usability/aesthetics. Care is being moved from hospitals to outpatient settings, and savvy consumers are demanding a better patient experience. Medical equipment is being redesigned to make it more accessible (e.g., lowering the height of diagnostic and treatment tables) and quieter and to add finer-grained control functionality.

In many cases, mechatronics is supplanting traditional hydraulics for motion control, because these systems are simpler, less noisy, and smaller/lighter. Examples of mechatronics use in equipment include gantry systems for imaging, telescopic pillars for raising and lowering surgical tables, and actuation systems for hospital beds, examination couches, and stretchers.

About the Author(s)

You May Also Like