Gigafactory Will Create a Giga-Glut

September 9, 2014

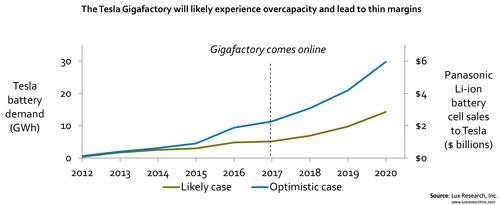

Tesla Motors' proposed Gigafactory won't dramatically transform the cost of electric cars, and it might create a glut of lithium-ion batteries in the marketplace, a new study says.

The study, The Tesla-Panasonic Gigafactory: Analysis of Li-Ion Cost Trends, EV Price Reduction, and Capacity Utilization, predicts that the Gigafactory concept will save just $2,800 per battery pack and will fail to produce the huge sales numbers that Tesla has projected. "In the grand scheme of things, the Gigafactory will reduce costs, but it won't be enough to significantly impact the market," Kevin See, senior analyst at Lux Research, producer of the study, told Design News.

Tesla's Gigafactory, announced earlier this year, is considered one of the most ambitious manufacturing efforts in American business history. It could potentially produce about seven times more battery capacity, employ 16 times as many people, and consume about 15 times as much land as today's biggest battery plants. Proponents of the concept hope that it will drive down battery costs to a point that would make electric cars desirable for mainstream buyers. Tesla has said that for the Gigafactory to reach its production goals, the company will need to sell 500,000 electric cars per year by 2020.

Lux Research's new study, however, predicts that Tesla won't come close to that figure. Using a demand model based on market size and competition, Lux projects sales of about 240,000 Tesla cars per year in 2020. Moreover, battery costs would not drop to the hoped-for $150/kWh level, but rather would stop at about $196/kWh. Given such costs, a 48-kWh battery would run about $9,400.

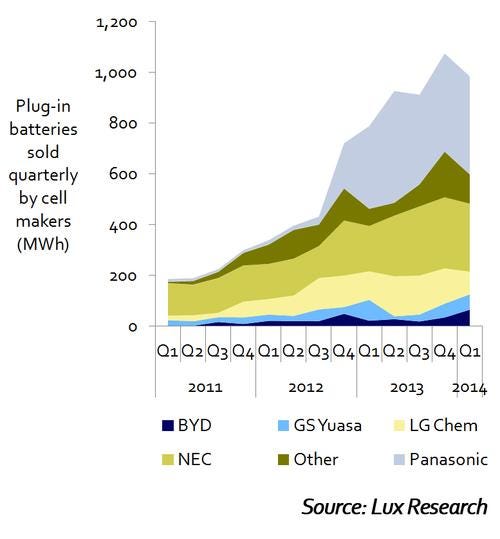

The failure to sell the stated 500,000 cars per year would create a serious lithium-ion battery overcapacity, the study says. "We already have an overcapacity of lithium-ion batteries right now," See told us. "So they are adding capacity into a market that already has an overcapacity."

Tesla has said the Gigafactory would have a 35-GWh capacity, which is about seven times more than Nissan manufactures for its Leaf electric car and about 35 times more than LG Chem makes at its Michigan-based factory.

See told us that if Tesla builds out to full capacity and fails to sell its stated number of cars, it probably won't be able to unload the entire 57% battery overcapacity to other automakers, or into other applications, such as grid storage. "Many of the supplier-user relationships are already locked up," he said. "Automakers tend to have their own preferences about design of the cell and integration of the cell into the battery pack. It's unrealistic to assume Tesla could sell those batteries into other cars." See added that the grid storage market, while growing quickly, isn't big enough to absorb an overcapacity of that size.

The larger question, however, is how the lower sales figures and overcapacity would affect Tesla. "It would certainly be a big blow, especially if Tesla builds out to full capacity," See said. "But even if it happens that way, it won't happen overnight, and there will be some opportunity for dynamic response to customer demand."

The performance of the Gigafactory will also affect suppliers and investors, See told us. Panasonic will contribute about 35% of the initial $4 billion required to build the factory, and many investors and material suppliers will be affected, as well.

"They're off-loading some of the risk by having suppliers pay to participate," See said. "So there's definitely a risk for all the suppliers, and those suppliers need to understand the numbers inside and out. We are preaching caution to them."

Related posts:

About the Author(s)

You May Also Like