Electric Supercharger Provides Boost for Gas & Diesel Engines

October 7, 2011

In 2007, eCycle Inc. and Ogura Industrial began collaborating on an electrically driven supercharger. Most normally aspirated diesel and gasoline engines benefit from the electrically driven supercharger, which offers increased fuel economy and engine performance, as well as emissions reductions, with significantly lower development and cost.

The companies are now focused on the auto and truck industries, and the new device will be an add-on to existing technologies in stationary and vehicular platforms, where a belt-driven supercharger accessory is not mechanically possible or attractive.

Ogura manufactures environmentally friendly, next-generation, roots-style, positive displacement superchargers, and eCycle is a leading manufacturer of low voltage, high current, high efficiency brushless motors and generators. Combining the two components creates a powerful, low voltage electric supercharger ideally suited for vehicular use. The complete system includes eCycle's SolidSlot brushless motor and buck-boost regulator, Ogura's supercharger, and a low-voltage battery.

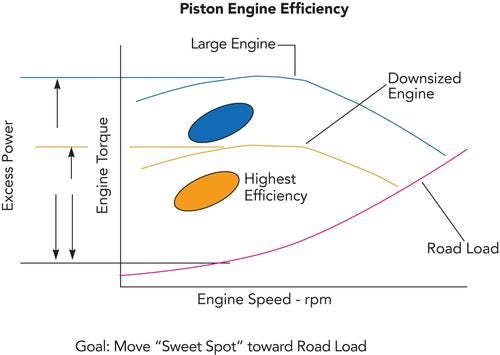

The operations principle is relatively simple. The electric supercharger supplies instant, variable boost, independent of engine speed. This enables faster acceleration, while allowing increased fuel efficiency and cleaner emissions.

The package can be readily integrated with a variety of engines in automotive, mass transit, truck, and marine platforms. Further, several components associated with inefficient superchargers have been eliminated while ultimately delivering increased performance and efficiency at low voltages. Though the benefits of supercharging and turbocharging are well established, this is an innovative approach.

The Ogura blower is a roots-style, positive displacement supercharger that works by pulling air through a pair of smoothly meshing rotors. These rotors have a unique design and are connected internally by a gear set that positions them 90 degrees apart. As the rotors turn in opposite directions, air is trapped in the pockets formed between the rotors and the housing. For every revolution of the rotor, a volume of air is pumped from the inlet to the outlet. Ogura's specially-coated rotors and the use of similar materials allows expansion rates to be tightly maintained.

eCycle achieves significant electrical improvements by employing its SolidSlot construction. This represents third generation, permanent magnet, brushless motor technology. The SolidSlot brushless motor/generator is named for its design, which replaces traditional copper windings with solid bars of aluminum. Slot fill exceeds 90 percent, compared to 50 percent for traditional windings, resulting in machines with super low resistance and thereby high current capacity.

Manufacturers and users will realize increased profitability with systems that are higher in power density and efficiency. Both Ogura and eCycle say that vehicle hybridization is the area that will see the most impact from this technology.

About the Author(s)

You May Also Like