Lightweight AHSS Automotive Design: Pushing the Envelope

November 12, 2013

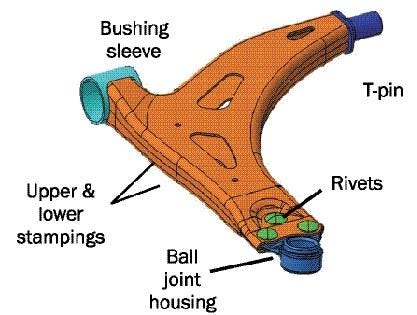

Today's average North American light-duty vehicles include passenger cars, crossovers, SUVs, and pickup trucks. All together, this fleet of vehicles averages 60 percent steel by weight, according to recent studies conducted by Ducker Worldwide and Mega Associates. Steel is dominant in the body and chassis. It can be found in most hang-on components, such as suspension parts, bumpers, and closures like doors and liftgates. But, in truth, weight is not helpful to a vehicle. The more mass a vehicle has to carry, the harder the engine has to work to propel it, the brakes have to work to stop it, and the suspension has to work to manage the handling. The vehicle also consumes more gasoline for every mile traveled.

With the introduction of the most recent Corporate Average Fuel Economy (CAFE) standards by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) for 2012 through 2025, car makers must essentially double the fuel economy of their vehicles. These new standards call for increasing fuel economy from an average value of 27.5 miles per gallon (MPG), a level in effect before the new standard was enacted, to 54.5 MPG as measured on a standard EPA dynamometer driving-cycle test including certain credits. This is a big challenge -- one of the biggest ever faced by car designers planning to sell cars and trucks in the US.

All car companies are looking for ways to design more fuel-efficient cars. This includes making engines burn less fuel through the use of technologies like direct injection, turbocharging, and stop-start. It also includes improving efficiencies at all speeds by incorporating eight-speed and higher-speed automatic transmissions. Besides all of the effort spent on the powertrain, every car company is seriously looking at ways to reduce vehicle weight to help pass the tough new standards. That means the existing steel structure, which represents the biggest share of a vehicle's materials content, is being examined by aluminum, magnesium, and plastics companies as a giant opportunity to increase automotive sales of their materials.

The questions are: Can the steel industry answer the lightweighting challenge by delivering new steel products? Can it enable car companies to achieve CAFE targets without having to switch to more expensive, low density materials? The answer is yes. It may surprise many people to learn that new steel products, called advanced high-strength steels (AHSS), have been working their way into vehicles so significantly in the last 10 years that they have been characterized as the fastest growing material in vehicles by market research firm Ducker Worldwide.

The use of these new AHSS products has required a new nomenclature for different types of automotive steels. For example, dual phase (DP) refers to a combination of hard and soft metallic phases, which gives the steel an outstanding combination of strength and formability. Transformation induced plasticity (TRIP) includes a metallurgical phase that transforms as the steel is stamped or deformed, enabling even greater formability and strength to be obtained. Complex phase (CP) includes several metallurgical phases in the steel microstructure, which impart strength and forming advantages in special cases like bending or hole expansion.

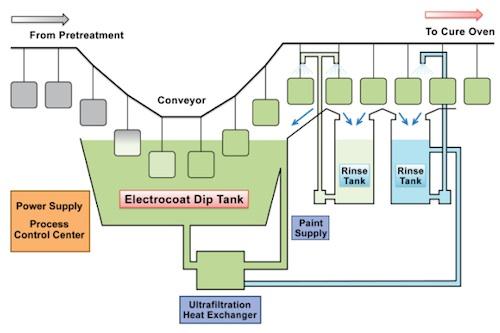

In contrast to shifting to low-density materials like aluminum, magnesium, and composites, car makers can keep intact their proven current manufacturing process -- for example, stamping presses, electric resistance welders, and paint shops -- with only some minor adjustments. Lighter AHSS parts are typically thinner than their predecessors, but they flow through the same operations in stamping and assembly plants. Most competing materials require a sizable investment in different processes, such as riveting, adhesive bonding, or injection molding -- all of which can lower production throughput and increase the capital investment required for new models.

About the Author(s)

You May Also Like