BBi Autosport and Autodesk Team-up for a Win, from Custom Race Cars to High-Performance Parts

The automotive aftermarket leader revs-up for the Pikes Peak Race to the Clouds using the Fusion 360 cloud platform.

February 9, 2023

Sponsored by Autodesk

Trent Still

The love of autosport is tied to a passion for boundary-pushing perspectives and practices. It's a passion based on a deep need to instill uniqueness in a world of mass production. An impact every car enthusiast dreams of having.

BBi Autosport is doing just that: Taking what it learns from its custom race cars and creating high-performance aftermarket parts for its consumer-products business.

BBi Autosport is an aftermarket tuning shop founded in 2005 with one foundational goal, to return artistry and craft to tuning and customizing what it calls the "phenomenal, dynamic, wildly versatile canvas" that is Porsche. But BBi and the team behind it are more than stewards of the Porsche brand; they're innovators, dreamers, and doers when it comes to designing and crafting their own hyper-performance vehicles. "These cars can do anything: hill climbs, off road, ice racing, rally racing, endurance races," says Betim Berisha, founder of BBi Autosport

Pikes Peak: Race to the Clouds

The Pikes Peak International Hill Climb, also known as The Race to the Clouds, is an annual hill climb to the 14,100-foot summit of Pikes Peak, Colorado. It's relatively unchanged from its century-old roots. From a racing perspective, Pikes Peak is unique. It's a single lap up a mountain at an extremely high elevation with extremely thin air. The aim is to see who can cover the 12.42-mile course the fastest while navigating the unrelenting obstacles the Peak throws at you.

Wind, weather, lack of oxygen, 156 turns to navigate, and sheer cliffs await the racer who makes a mistake. At its core, The Race to the Clouds encourages the most intrepid individuals and crews to test their limits and those of their creations.

This presented a challenge that the BBi team decided to meet head-on. The conditions can be very taxing on a car at the race’s high altitude. The tires don't work as well, the cooling system and aerodynamics don't work, and the engine doesn't create as much power. With all these factors in mind, the team tackled set-out to build a complete car from scratch.

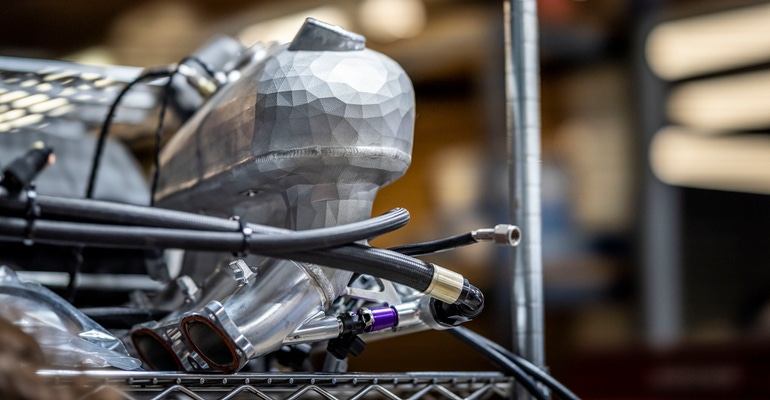

Enter the "Hoonipigasus," aka "The Pig." Featured on Porsche’s website, it’s a beastly 1,400 HP mid-engine AWD rally racer built entirely using Autodesk Fusion 360 in partnership with Hoonigan Racing.

The race to the finish line -- or technically to the starting line of the race – was compounded by an insanely busy schedule, long lead times, and the pandemic-fueled delays. To reach completion, the team needed to simultaneously design, engineer, fabricate, and test The Pig.

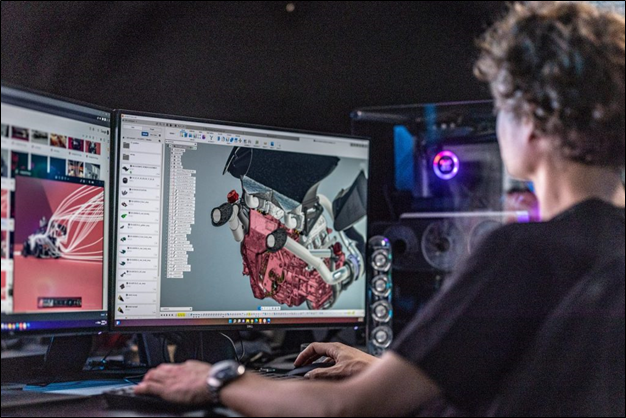

Traditional design and manufacturing tools didn't give the team what they needed to work concurrently and collaboratively. They turned to Autodesk Fusion 360 to meet the challenge, allowing them to bring aggregated data into one centralized location. Integrating CAD, CAM, CAE, and PCB in a single cloud product development tool made turning prototypes into production-ready parts easy.

"Collaborating on the cloud turned the chaos into an organized chaos; Fusion 360 enabled us to design, validate, build, and get straight to the racetrack very quickly."

—Dmitry Orlov, CTO, BBi Autosport

The team's scan-to-CAD workflows were simplified with the suite of mesh tools Fusion 360 offers for slicing and referencing. Additional tools including generative design allowed them to run flow analysis to generate recommended outputs and design parts manufactured to their desired specifications.

"Autodesk Fusion 360 enabled us to move seamlessly through every stage in our development process, whether we were designing an engine, chassis, or even the smallest component.

—Betim Berisha, founder, BBi Autosport

Even with the most effective plans, motorsport races are unpredictable by nature. And as autosport often reminds us, every plan only works until the first hurdle or heartbreak shows itself; The Pig dropped a valve before even qualifying for the race. While everyone on the team looks forward to the 101st Race to the Clouds, they've been able to take what they've learned to create high-performance aftermarket parts for the BBi Autosport consumer-products business.

In fact - they've already gotten back to the drawing board quickly iterating on new components and existing components in Fusion 360's manufacturing tools to deploy at 101st running of Pikes Peak International Hill Climb.

BBi's racing division is a perfect example of how to win the engineering race despite losing a single lap. The way they do it is seen in the simple but effective and capable tools they use. Fusion 360 lets BBi prototype, test, and iterate to bring concepts from design to manufacture quickly — in a matter of days — to get new parts to market. Orlov says the streamlined integrated cloud-based product development environment takes a grassroots motorsport shop like us and elevates us to a level playing field."

About the author

Trent Still, Senior Technical Marketing Manager with Autodesk, is a technologist working in design and manufacturing futures. He brings his experience in multiple industry disciplines, from architecture to advanced manufacturing, to bear in bringing projects and products to reality to influence the future of how things are made.

Trent Still, Senior Technical Marketing Manager with Autodesk, is a technologist working in design and manufacturing futures. He brings his experience in multiple industry disciplines, from architecture to advanced manufacturing, to bear in bringing projects and products to reality to influence the future of how things are made.

You May Also Like