Welding Gun Not So 'New & Improved'

November 12, 2014

Tweco is a well-respected brand in the welding community. My Miller MIG welding rig is an older 220 unit, but it is one of the smaller units that runs on 220. It was originally equipped with an economy MIG gun that was made by Tweco. This gun was somewhat rinky-dink, for lack of a better technical term, but to its credit, the thing has worked and worked and worked.

Recently, I had been working on a fairly large project requiring a lot of welding. I had really been putting the wire through it, and it was apparent that I was going to need to replace the liner after hundreds of hours of satisfactory service from the original gun.

In lieu of reworking a mediocre gun, I opted to buy a new, upgraded Tweco gun. It had a longer cord, which was great, and it was much higher quality. It was Tweco's latest offering: The Fusion 220.

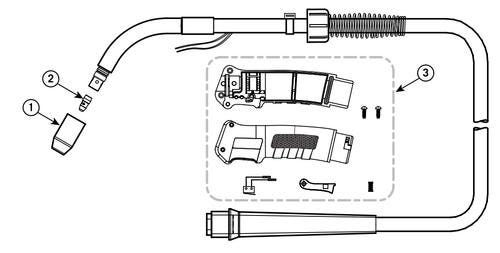

When I got it home, it was obvious that it was a much higher quality unit than the one it was replacing. There were "improved" features, and it was supposed to save on consumable costs; the consumables being typically the nozzle and the tip (items 1 and 2 in the diagram below).

I immediately noticed that this gun was allowing me to perform better welds than my old gun, so I was off to a good start.

But then the first problem reared its head. I noticed that the tips tended to bind up fairly easily. I was using a quality wire, but even so, if for some reason the arc didn't start, the wire would bind and buckle just enough to gall the tip (item 2 in the diagram) to the point that the gun would need to be disassembled and the tip repaired with a welding torch file (a tiny, round file used for cleaning out the carbon in oxy-acetylene torches) or it would have to be replaced.

This was a new nuisance that I was not enjoying. I just wanted to weld and get my project done.

Next was a major problem that occurred while I was performing overhead welding. When you do overhead welding, slag tends to drop. In the case of this new gun, any slag that found its way into the nozzle opening would inevitably wedge itself between the central brass conductor (which conducts electricity to the tip and subsequently to the welding wire) and the outer copper shield.

Any time the shield would touch the work, the gun would "arc out" against the work. This was not supposed to happen. As you can see in the picture below, there is a fiberglass insulator between the central brass conductor and the outer copper shield. There should be no conductivity between the two. But as you can also see, a ball of steel slag has bridged the gap, allowing electricity to flow to the shield.

My old gun never had this problem. There was no annular cavity like the one shown in the photo. Any time that slag did get into the old nozzle, it was open enough to be able to stick a flathead screwdriver into it and clean it out.

This new design is perfectly designed to trap slag and there is no way to get it out. That means I'm going through expensive consumables like crazy, which is not good. The consumables are called "Velocity," and I think maybe that refers to how fast you are going to go through them.

I'm pretty sure that this MIG gun wasn't designed by monkeys, but I'm not so sure that the engineers who designed it ever did any welding. It literally only took a few hours in my shop to discover this significant design flaw. On a prototype, this kind of problem is OK, but it should be identified and corrected before it becomes a consumer-grade product.

Tell us your experiences with monkey-designed products. Send stories to Jennifer Campbell for Made by Monkeys.

Related posts:

About the Author(s)

You May Also Like