Turning Up the Heat: Considerations for High-Temperature Applications

December 4, 2014

Customers frequently ask salespeople about the maximum service temperatures for various high-performance plastics. In many cases, an engineer has come across a single piece of information such as a material's heat deflection temperature, glass transition temperature, or continuous service temperature, and the individual mistakenly believes that a single property value specifies the maximum temperature at which a thermoplastic can be used.

Although the maximum operating temperature for a plastic material may seem like a simple question, the answer actually involves considerable complexity, and multiple characteristics of the polymer must be considered when making this determination. The purpose of this article is to examine some of these characteristics and provide a framework for richer discussions with customers about the use of plastics in high-temperature applications.

Softening Behavior: How Soft is too Soft?

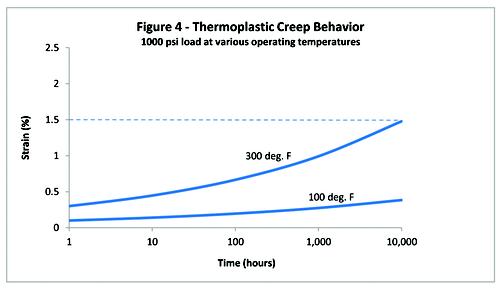

Anyone who has microwaved leftover food in a plastic container has noticed the loss of strength and modulus (stiffness) of the container as it increases in temperature. This inverse relationship between the temperature and modulus of a thermoplastic can be represented on a graph as shown in figure 1.

This graph yields important information about the mechanical properties of this polymer at various temperatures. This particular thermoplastic maintains much of its stiffness up to approximately 300F/149C and it rapidly loses stiffness at temperatures above 300F/149C. Depending on the mechanical property requirements for the application, this polymer may or may not be suitable for use at temperatures above 300F/149C.

At this point it is important to mention that the graphs presented in this article can rarely be found in stock shape manufacturers' technical literature; however, they are almost always available in the design guides published by the major plastic resin manufacturers. Thermal properties graphs can also be found in many plastics reference manuals. One excellent example is The Effect of Temperature and Other Factors on Plastics and Elastomers, by Laurence McKeen, which is part of the Plastic Design Library series published by Elsevier B.V.

Thermal Degradation: How Long Will the Material Maintain its Strength

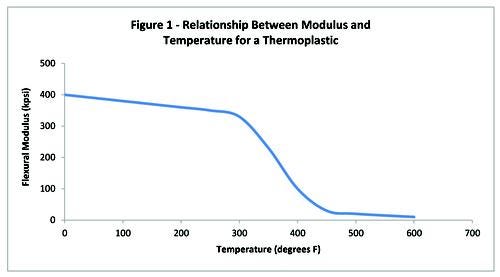

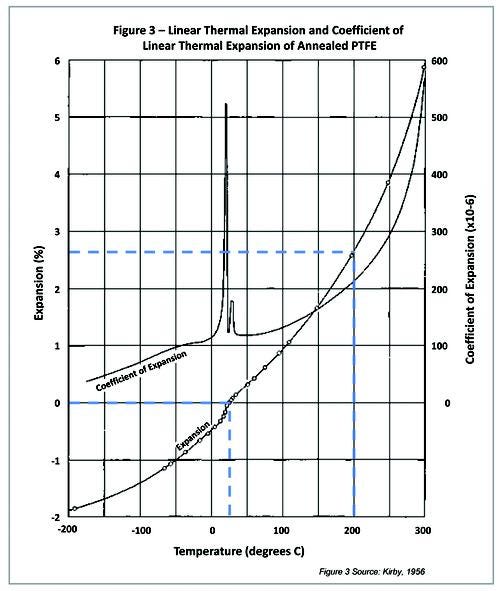

Thermoplastics exposed to elevated temperatures for long periods of time will generally become brittle and lose both mechanical strength and toughness. This process will occur more slowly at moderate temperatures and more quickly as the operating temperature for a material is increased. This behavior is evident in older cooking appliances, which often have degraded and chipped plastic handles. The rate of degradation will vary from material to material and the degradation rate for a particular polymer can be represented on a graph as shown in figure 2. A 50% loss of initial tensile strength is used as a standard to show the degradation rate of a material at various temperatures.

As shown on the graph, this particular plastic material will lose half of its initial tensile strength when placed in a 300F/149C operating environment for 1,000 hours. When the same material is placed in a 400F/204C operating environment, it degrades more rapidly, losing half of its initial tensile strength in only 100 hours. Therefore the suitability of this polymer for use at elevated temperatures depends on the operating temperature for the application, the minimum tensile strength required for the part to perform, and the desired service life of the device. Additionally, the design engineer may wish to include a safety factor, especially if the device is for a critical-service application such as aerospace or medical equipment.

Thermal Expansion: Will the Material Grow too Much?

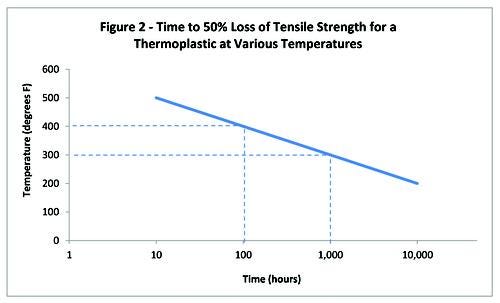

Plastics generally have a higher rate of thermal expansion compared with other industrial materials such as metals, wood, or ceramics. This is further complicated by the fact that the rate of expansion for many plastic materials changes throughout their operating temperature range. For example, the coefficient of thermal expansion (CTE) of PTFE (polytetrafluoroethylene) is shown on the graph in figure 3.

Although the coefficient of thermal expansion of PTFE is usually simplified and reported as a single number, the graph shows that the actual growth rate of PTFE changes as the material is heated from -328F/-200C to 572F/300C. In the case of PTFE, the rate of thermal expansion is lower below 77F/25C and becomes increasingly higher above 77F/25C.

When plastic and metal components are used together in a device that must operate over a wide temperature range, the relatively high thermal expansion of polymers becomes an important design consideration. For example, the blue lines on the graph indicate an operating temperature range of 77F/25C to 392F/200C for a particular application for which PTFE is being considered as a possible material. For this example, the PTFE will be used in contact with a 1-meter-long steel mating part. Throughout this temperature range, PTFE has a coefficient of thermal expansion of approximately 151 x 10-6 per degrees C. In contrast, steel has a much lower CTE of approximately 13 x 10-6 per degrees C. This results in a CTE mismatch of 138 x 10-6 per degrees C when PTFE and steel components are used together in the finished device. In this example, when the part is heated from 77F/25C to 392F/200C, at the upper end of the temperature range the PTFE component will grow approximately 24 mm longer than the mating metal part. This dimensional mismatch may make PTFE unsuitable for the application even if the other thermal characteristics of the material such as loss of modulus and the rate of thermal degradation are acceptable.

It is noteworthy that there are a number of ways to reduce the CTE of a plastic material including introducing fillers and reinforcements into the formulation. This is a common practice that is often used when dimensionally stable plastics are required for elevated temperature applications.

About the Author(s)

You May Also Like