The Pipe Sealant Was Not Compatible With Jet Fuel

December 17, 2013

Several years ago, we had a customer who bought a jet fuel dispenser cabinet from us, and it was connected to an underground storage tank. It was installed and worked well for about a month, when the customer started to complain about how our "pump keeps losing prime." Every time they wanted to refuel their corporate jet they had to put the system in the recirculation mode, which caused the pumped fuel to pass through the filter and back to storage to flush out air in the suction line.

.jpg?width=700&auto=webp&quality=80&disable=upscale)

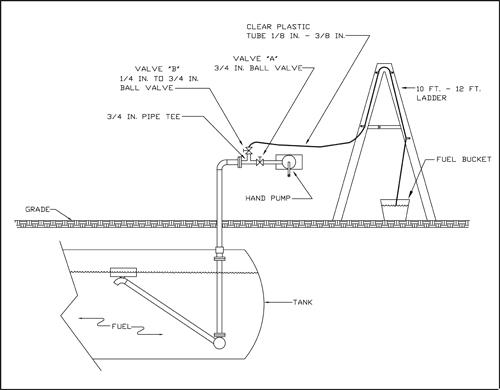

The contractor had tested the pipe by pressurizing it with air and waiting for several hours, looking for a drop in pressure. I devised a tester and built it from odds and ends I had handy. I connected a flange to his four-inch suction line. I reduced this down to just 3/4-inch and then split it into two ball valves, one connected to a hand pump and the other to 20 feet of small plastic tubing. I ran the plastic tubing up a tall ladder and then down into a bucket filled with fuel.

I opened the valve to the hand pump and closed the other. I operated the hand pump until I got fuel so I knew the suction pipe was full of fuel. I closed that ball valve and opened the other.

The force of the fuel trying to drop back to the tank pulled a relative suction on the plastic tube and the bucket of fuel, but the ladder was tall enough to stop a syphon, creating a manometer. Because we were using fuel with a density 80% of water, our little tester provided about 3.5 feet of travel for a 1 psi change in pressure/suction.

We stood and watched the level in the plastic tube slowly moved downward at about 12 inches per hour. We knew the level in the suction pipe was moving down at the same rate. We had found the problem, but not the cause.

Reluctantly, the contractor broke his concrete and found the underground pipe connections "hand tight." He was baffled, as he had tightened the pipes himself with big wrenches. But we quickly learned the cause. When he unscrewed the connections, there was very little pipe sealant left. His pipe sealant was not compatible with jet fuel -- which is a big surprise since jet fuel is only a very good grade of kerosene.

We resealed the pipe with Teflon tape and the system is in service to this day. Since then we have learned to listen to the pipe itself, to detect internal leaks by bubbling, and to listen to the tank top connections for hissing or dribbling, also signs of suction leaks.

Have you had trouble with Teflon tape? Apply it clockwise under tension, but then put a tiny amount of Vaseline on it before assembly. The Vaseline helps keep the tape from being damaged during the first few turns of the thread, but be careful not to over-tighten, Vaseline and Telfon tape together lowers friction!

This entry was submitted by Jim Gammon and edited by Lauren Muskett.

Jim Gammon is the president of Gammon Technical Products Inc., a New Jersey-based manufacturers of US-made fuel testing and handling equipment. He participates in activities at ASTM, SAE, NFPA, and other industry groups, and holds several patents.

Tell us your experience in solving a knotty engineering problem. Send stories to Lauren Muskett for Sherlock Ohms.

Related posts:

About the Author(s)

You May Also Like