Solar Impulse 2 Flies New Materials

April 24, 2014

The second version of the 100% solar-powered airplane, Solar Impulse, has been completed. It debuted April 9 in Payerne, Switzerland. The new airplane will be the one used in next year's attempted around-the-world flight.

Last year, the first prototype model of the Solar Impulse plane completed a piloted, cross-country flight over the US from California to New York. The new Solar Impulse 2 model will undergo several test flights during 2014 before its big flight in March 2015.

The new plane will be powered by about 17,200 solar cells on the wings, about 50% more than the first version. Made of lightweight materials, the entire aircraft weighs 2.3 metric tons (2,300 kg), nearly 50% more than Solar Impulse 1. Its wingspan is 72 meters (236 feet), slightly larger than its first incarnation and about the same as the largest passenger airliner. Several of its materials have been designed by Bayer MaterialScience and Solvay. You can watch the official presentation video (over three hours) here, and a 20-minute walk-around video with closeups and descriptions of the plane here.

Click on the image below for a closer look at the Solar Impulse 2.

Solvay says its contributions include the Halar ECTFE ultra-thin polymer film that protects the solar panels and solar cells against moisture, the Solstick PVDF Solef adhesive tape closing gaps between solar cells, and PVDF Solef and F1EC solvent for protecting the plane's 640 kg of lithium-ion batteries and for improving energy density. The batteries, recharged during the day by the solar cells, will allow the plane to fly at night.

Other Solvay materials include Fomblin PFPE lubricant for mechanical parts; strong and lightweight materials, such as specialty polymers Ketaspire PEEK and PrimoSpire SRP for fasteners and screws; and Polyamide 6 Sinterline for 3D-printing complex mechanical parts, such as lighting clips or the housings for cockpit equipment, using selective laser sintering (SLS). The wings' carbon-fiber honeycomb sandwich structure, which helps the plane stay lightweight and strong, is made with paper impregnated by Solvay's TorlonPAI polymer.

Both planes are heavy users of materials from Bayer MaterialScience. In the first model these included high-performance polyurethane foams in the cabin, motor gondolas, and wing tips, and also highly transparent polycarbonate and films in the cabin window and other locations. The cockpit insulating material is a high-performance insulating Baytherm Microcell foam, according to a press release. This material is also used in the aircraft door. The rest of the cockpit shell is made with a different type of polyurethane rigid foam. Bayer was responsible for designing the Solar Impulse 2's entire cockpit shell.

A Bayer rigid polyurethane foam is also used to insulate the batteries. A polyurethane/carbon-fiber composite material is used for door locks, and the window is made of high-performance polycarbonate. The silver-colored coating that covers large areas of the plane's exterior and the adhesives that keep the wings' fabric attached are also made of raw materials from Bayer.

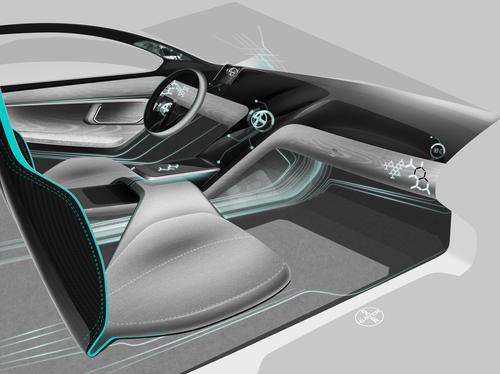

Bayer says it expects to use the "flying laboratory" of Solar Impulse planes to help develop its existing products and test new ones. A few days before the Solar Impulse 2's unveiling, Bayer announced an integrated cockpit design concept for automotive interiors based on polycarbonate.

The Solar Impulse project began in 2003. The first test flights began in 2009. The first aircraft completed test flights within Europe and to North Africa while construction began on the slightly larger Solar Impulse 2. The total in-air flight time in 2015 is expected to be 20 days, but breaks to relieve the pilot will make the entire journey last about three months.

Related posts:

About the Author(s)

You May Also Like