Shrimp Club Inspires Stronger Aerospace Composite

May 9, 2014

A couple years ago we told you about researchers studying the structure of the mantis shrimp's club to improve military body armor. Now, a slightly different team has come up with that material, and the carbon-fiber-reinforced composite is both stronger and resists impact better than similar materials typically used in aircraft.

The team, headed by professor David Kisailus at the University of California, Riverside, Bourns College of Engineering, originally had a goal of developing a material that's one-third the weight and thickness of existing body armor. In 2012, they analyzed the structure of the mantis shrimp's club-like arms, which are extremely strong, tough, and lightweight. Kisailus runs UCR's Biomimetics and Nanostructured Materials Lab.

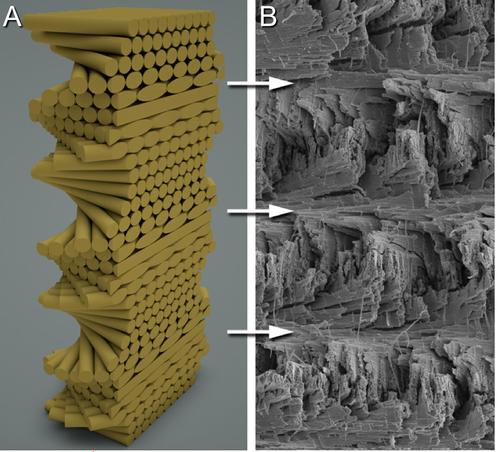

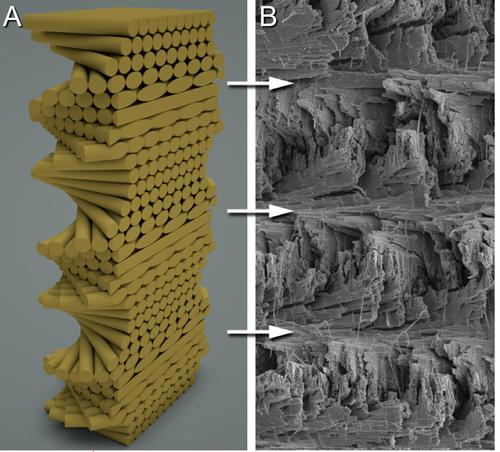

The animal uses its clubs to destroy mollusk shells and crab exoskeletons, accelerating underwater faster than a .22 caliber bullet. The team found that the clubs are highly complex structures made of three specialized sections, which work together to make a tougher material than many engineered ceramics. One section, the endocuticle region, has a structure made of spiraling, or helicoidal, mineralized fiber layers that work like a shock absorber. Each layer is rotated slightly from the layer below it.

In an article in the journal Acta Biomaterialia (purchase or membership only), the UCR researchers describe their new carbon-fiber-epoxy composites. This time, they were assisted by researchers from the University of Southern California and Purdue University. The new composites were designed to emulate the helicoidal, layered structure of the shrimp club's endocuticle. The team used both experimental and computational methods to discover that "a helicoidal architecture is shown to reduce through-thickness damage propagation in a composite panel during an impact event and result in an increase in toughness," according to the article abstract.

They created carbon composite structures with helicoidal layers arranged at three different angles between 10 degrees and 25 degrees. Two control structures included one with unidirectional layers, and another with the typical quasi-isotropic structured layers used in aerospace carbon composites today, where succeeding layers are rotated about 90 degrees in different directions.

To test the strength of the different structures, the researchers used a drop weight impact testing system similar to that used in the aircraft industry to assess dent damage, external visual damage, and internal damage. The new helicoidal structures suffered 20% to 50% less dent depth damage than the industry-typical quasi-isotropic structures, and a few split fibers versus major external fiber damage and punctures. Using ultrasound, they found that conventional quasi-isotropic samples experienced catastrophic internal rupturing, but damage to the new helicoidal samples spread laterally inside the structure.

In a compression test, which compressed samples until they broke, the new helicoidal material had about 15% to 20% more residual strength after breaking than the conventional quasi-isotropic material. The team used finite element modeling to understand failure modes and give ideas about modifying the structures. Carbon composite designed on this helicoidal model can be used in the frames of planes and cars, as well as in body armor and sports equipment, like football helmets.

Research was funded by the Air Force Office of Scientific Research and the National Science Foundation. It will be continued with a new $7.5 million grant from the Department of Defense.

Related posts:

About the Author(s)

You May Also Like