Recycled Tires Find New Use in Car Batteries

September 26, 2014

Recycling is not only standard in American households, it's becoming a big research trend, and now, a team out of the Department of Energy's Oak Ridge National Laboratory is using materials from old tires to design new car batteries.

Researchers are recovering graphite powders from carbon black used in tires to develop anodes in lithium-ion batteries that perform better than standard graphite materials, Mariappan Parans Paranthaman, one of the researchers on the project, told Design News.

Researchers so far have only tested batteries in coin-cell configurations, in which they have performed comparably or better than typical lithium-ion batteries, he told us. After 100 cycles the capacity measures nearly 390 milliamp hours per gram of carbon anode, which exceeds the best properties of commercial graphite, according to researchers.

They attribute the performance boost to the microstructure of the carbon taken from tires, Paranthaman told us. "Since it forms a one dimensional structure ... with a porous microstructure, it performs better than standard graphite materials. However, we still need to demonstrate on a large format or pouch cells," he added, something that is in progress.

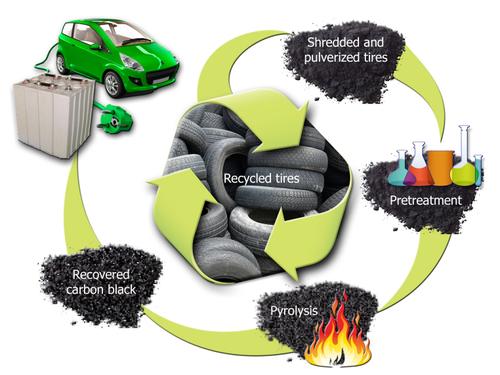

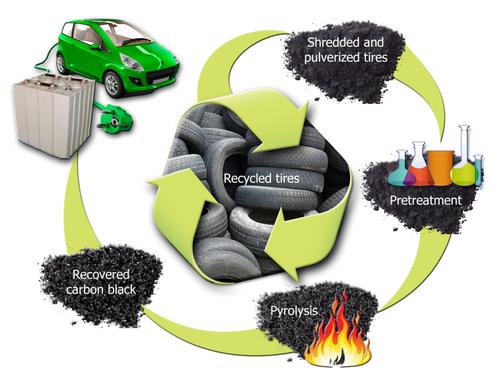

The method of extracting the powders is a fairly simple process that uses a proprietary pretreatment, after which the material goes through an acid soak followed by pyrolysis. The process is explained in detail in a paper co-authored by Paranthaman and fellow researchers published in RSC Advances.

"It is not a complex process," Paranthaman said. The method recovers up to 45% of the tires. Meanwhile, the hydrocarbons and sulfur present in the leftover materials won't go to waste, either, as they can be converted into diesel-type bunker fuels. Because the graphite powders can be affordably and safely extracted from tires, they can be used for anodes in the mass production of large batteries, he told us.

This represents a significant market opportunity, as well as fills a need for an inexpensive, environmentally benign composite anode material with high-surface area, higher-rate capability, and long-term stability, according to researchers, who are currently seeking partners to mass-produce the material.

"We are looking for industry partners that can scale up our process to produce several tons of graphite powders and demonstrate the fabrication of large lithium-ion batteries," Paranthaman said.

Related posts:

About the Author(s)

You May Also Like