Novel Material Eyed to Create Flexible Thermoelectric Generator for Wearables

A combination of three materials provides various properties for a composite that can be used to print devices that can harvest energy from body heat.

April 24, 2020

Developing alternative power sources to bulky batteries for wearable applications is a priority for developers of these types of technologies. One of the ways to do this is through the harvesting of body heat, which can be a good source of natural energy.

|

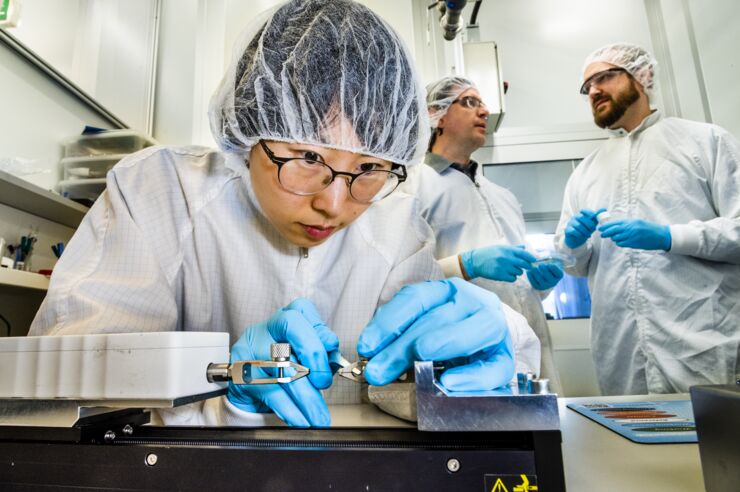

The team who created a soft and stretchable thermoelectric generator that can be used to turn waste heat into electricity. Shown are the researchers Nara Kim, with Xavier Crispin and Klas Tybrandt in the background. (Image source: Linköping University) |

Using this principle, researchers at the Laboratory of Organic Electronics at Linköping University have developed an organic composite material that balances thermoelectric properties with flexibility, making it a viable candidate to create devices that can use body heat to power wearables.

The team combined three materials in their work to provide the resulting material with its properties: PEDOT:PSS; a water-soluble polyurethane rubber; and an ionic liquid.

Combined, these materials provide the various characteristics of the material, with the PEDOT:PSS providing the thermoelectric properties needed to generate electricity from waste heat; the rubber providing the elasticity; and the ionic liquid providing the softness, said Nara Kim, a postdoc and principal research engineer in the Laboratory of Organic Electronics.

Researchers employed techniques to control the structure of the material both at the nanoscale and the microscale to create the combination of properties.

Creating Energy Harvesters

Typically PEDOT:PSS—the most common conducting polymer—in film form is too hard and brittle for use in wearables, Kim said. Combining it with the other materials provided the right balance to create a composite suitable for printing thin-film thermoelectric generators for wearable form factors, which need to bend and stretch to conform to body movements. ”The composite was formulated by water-based solution blending and it can be printed onto various surfaces,” Kim said in a press statement. “When the surface flexes or folds, the composite follows the motion.”

Moreover, fabrication of the composite is inexpensive and environmentally friendly, reducing the use of materials needed to create the new power source, researchers said. Comparatively, manufacturing typical batteries involves the use of toxic chemicals.

The team published a paper on its work in the journal Nature Communications.

Researchers believe their new material can be used to create both soft and elastic organic conducting materials not only for thermoelectric generators, but also for supercapacitors, batteries, and sensors.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco and New York City. In her free time she enjoys surfing, traveling, music, yoga and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like