LMD Additive Manufacturing Expands in Aerospace

The 3D printing processes of laser metal deposition (LMD) and directed energy deposition (DED) are revolutionizing how the aerospace industry designs and builds high-value components across the manufacturing spectrum from prototyping to production.

January 30, 2019

Aerospace components have long been fabricated using traditional manufacturing methods such as forging. That method requires significant post processing. 3D printing offers new alternatives. Laser-based additive manufacturing provides an alternative, single-step method for producing complex, multi-material, dense or porous, near net-shape parts that often outperform their traditionally manufactured equivalents, offering enhanced properties.

|

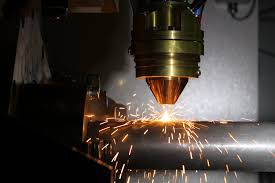

Formalloy is using laser metal deposition to 3D print aerospace components for rocket nozzles and heat exchange. (Source: Form Alloy) |

3D printing company, Formalloy, is producing parts using a laser-based process because of its ability to create new advantageous shapes. “Our technology is known as LMD. That’s a method where you blow power and heat it with a laser. You build the part layer by layer,” Melanie Lang, managing director at Formalloy, told Design News. “The first advantage of this process is the ability to achieve design features such as internal cooling chambers or multi-material components with two different metals in the same part. Those types of parts can’t be created by traditional manufacturing methods.”

The LMD process also reduces waste when using high-priced materials. “In a part that is entirely titanium, the LMD process offers the advantage of efficiency,” said Lang. “We’re much more efficient with the material itself using LMD. Also, there’s a lead-time advantage, since you don’t have to go through a tooling process to get the geometry you need.”

Lang will present the session, Metal Additive Manufacturing for Aerospace Applications, at the Pacific Design and Manufacturing show in Anaheim on Feb. 5. The session will cover:

Laser-based additive manufacturing as an alternative method for producing metal parts

The laser metal deposition process and key components

The display parts made from laser metal deposition, such as sample rocket nozzle components

There are many parts in aerospace that are now being produced through the LMD process. “LMD parts that were seeing in aerospace include sample rocket nozzle components,” said Lang. “Other examples include a heat exchange component that’s part of a rocket nozzle. The additive manufacturing geometry includes inlets in the wall that are for cooling.”

RELATED ARTICLES:

Many of the parts that are produced in aerospace cannot be produced by any method other than LMD. “Lattice structure are used to reduce material and weight. It would be hard to make these with any other technology,” said Lang. “You reduce weight but still get strength. Using LMD, you can create space in the component for quick cooling.”

Rob Spiegel has covered automation and control for 17 years, 15 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years, he was owner and publisher of the food magazine Chile Pepper.

|

About the Author(s)

You May Also Like