Assessing Compatibility of Adhesives for LED Assembly

December 9, 2013

Today's LED lighting devices are expected to perform reliably outdoors and indoors in industrial, commercial, consumer, residential, and architectural settings. These lights must stay bright for more than 36,000 hours, despite exposure to extreme temperatures, dust, dirt, and vibration and even in cases of underwater submersion.

The core of a white solid-state lighting (SSL) luminaire device is the LED (light-emitting diode). The LED is typically a metal-doped silicone carbide chip with a phosphorous layer. The phosphorus changes the typical blue light emitted by the die into whiter, warmer light colors. This assembly is attached to a substrate material and covered with a silicone encapsulant to protect the die and effectively transmit light.

For the manufacturer, adhesives, sealants, potting materials, and threadlockers bond and seal the LED assembly onto the associated substrates and enclosures, lowering manufacturing costs of the lighting assembly and helping ensure the long life of the LED.

But chemical interactions between the materials used in LED production can degrade the light emitted by the encapsulated chip. For example, when adhesives and sealants outgas, they release VOCs into the LED assembly. These VOCs cause the LEDs in the light modules to discolor, reducing the clarity and brightness of the LED light. This is especially common in closed systems, where the space between the chip, the silicone lens, and the external cover lens is a sealed environment with no ventilation to the outside atmosphere.

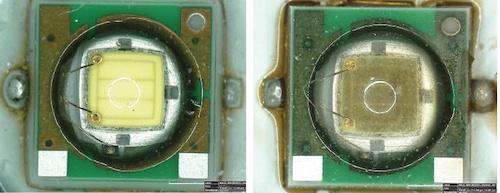

In a closed environment, the VOCs have nowhere to escape. Trapped organics migrate into the silicone lens and make contact with the LED die. If an incompatibility exists between the LED and VOCs, the LEDs discolor rapidly, often within hours of exposure. Light output levels drop and changes in the quality of the light's color or chromaticity occur. In extreme cases the device can fail completely (see figure 1).

LED discoloration is typically not permanent and can be reversed by removing the external cover lens or venting the closed system to release the VOCs. As the LED assembly equilibrates back to normal atmospheric conditions, the VOCs migrate out of the LED, and emitted light returns to its normal color and brightness.

By specifying only adhesives and sealants that meet compatibility requirements, LED manufacturers can eliminate these materials as a source of browning and help maintain the color point and consistent quality of their lighting devices. Careful adhesive selection during device design ensures that any incompatibilities between LEDs and adhesives never occur.

Using compatibility data to select the right adhesives

Typical adhesive and sealant applications include, but are not limited to, lens bonding, lens sealing, driver/circuit board potting, and threadlocking. The manufacturing process, the substrates being bonded, and end-use application of the final assembly dictate the adhesive chemistry that is appropriate and the cured properties the adhesive should offer.

All adhesive families can potentially be used on a luminaire. Epoxies and hot melts are appropriate for potting. Elastomers such as silicones, modified silanes, and urethanes offer flexibility for sealing applications. The rapid cure speed and strength of cyanoacrylates (instant adhesives) and methyl methacrylates make them excellent choices for tacking or bonding. Anaerobics are specifically designed for threadlocking and sealing.

With all these adhesive choices, the challenge is selecting the correct products that will be compatible with all substrates and assembly processes, without degrading the lighting device.

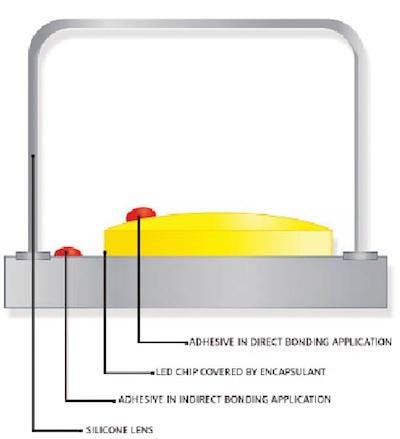

Adhesive applications on LEDs can be divided into two categories: direct, where adhesive is touching the silicone lens that encases the LED chip, and indirect, where the adhesive is within proximity of the silicone lens but does not touch it (see figure 2).

About the Author(s)

You May Also Like