3M Sharpens Assembly Focus on Info & Access to Experts

March 27, 2015

Instead of sifting through huge amounts of technical data sheets, various websites, and white papers looking for answers to assembly problems, engineers can now benefit from 3M's new initiative, 3M Assembly Solutions, announced this week at NPE2015. The company has organized its wealth of adhesive and tape solutions into six typical application areas, making it easier for engineers to find the best products to solve their real-world assembly and bonding problems. 3M is also making it easier for engineers to access internal experts for help in applying the company's products to their designs.

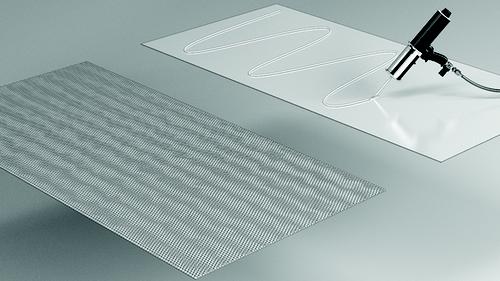

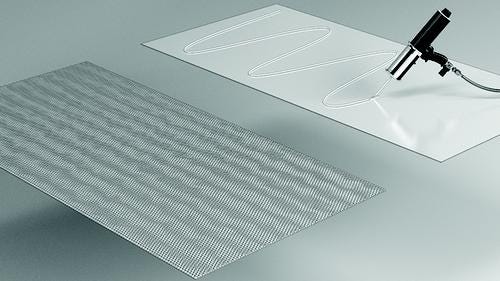

The service gives engineers assembly alternatives to mechanical fasteners, welds, and rivets. As we've often discussed in Design News, the range of available adhesives with various performance characteristics has broadened, for both structural and non-structural uses, in many industries. Some new structural adhesives for joining dissimilar materials can even reduce the need for fasteners or replace them entirely, and can be easily integrated into high-volume production lines. Others complement and reinforce rivets and welds. 3M has a broad range of adhesives and tapes ranging from repositionable to permanent, and for multiple industries such as automotive, aerospace, electronics, medical, packaging, and industrial.

MORE FROM DESIGN NEWS: Adhesives Get Tougher, Stronger, and More Versatile

On the 3M Assembly Solutions webpage you can find summaries of several common assembly situations where adhesives and tapes can be superior to more traditional methods, which help you determine initial feasibility for your design and production needs. These include panel-to-frame or stiffener-to-panel; small joint assembly; large surface lamination; mounting and trim attachment; gasket attachment; and sealing, potting, and encapsulating.

For each of these situations, use case examples are given and possible requirements of adhesives and tapes are listed. Clicking on each one takes you to an entire page devoted to a more detailed discussion of application requirements and what's needed for different materials used in these scenarios. Also included are appropriate 3M products, including comparative ratings of their performance and attributes across several critical design characteristics. Demonstration videos are available on the site, as well as an archived webinar.

After reviewing this information based on your unique design or process criteria, you can determine which options to consider. You can then inquire about discussing your specific design or production challenge with 3M experts, including considerations of essential factors like substrate materials, process, product life cycle, and environmental impact.

"We've brought together and simplified all this product information into six application areas, including possible product usage for each one," Mark DeLaForest, 3M marketing manager, told us. "We also want engineers to understand that there are different ways to assemble products using either a tape or an adhesive for the same application, depending on specific performance, processing or design criteria."

MORE FROM DESIGN NEWS: 9 New Adhesives Hold Things Together

3M has also streamlined its internal process for routing inquiries to its assembly solution experts, so they can communicate faster and in a more relevant manner, said DeLaForest. The person receiving inquiries when engineers fill out an "Ask a Design Specialist" form online is at a higher level of technical competency than the standard customer service person engineers would reach at the toll-free number.

"Although everyone uses the Internet to access product information and get details on what they're looking for, often engineers make a purchase decision based only on the information available on a website," DeLaForest said. "In the world of adhesives, and especially the more complex adhesives and applications, often written information isn't enough; there are too many variables. We want to provide better access to our experts who can work through and help solve design challenges and processing issues in customers' end-use product applications."

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 25 years, covering manufacturing materials & processes, alternative energy, machine vision, and all kinds of communications.

About the Author(s)

You May Also Like