Study Says AI Can Deliver Huge Financial Value to Industry

Engineers can use AI and deep learning for predictive maintenance, materials procurement, and product development.

June 29, 2018

A new study from McKinsey Global Institute shows that artificial intelligence and deep learning are finally starting to make big gains in industry. But the study’s authors say that many engineers still hesitate to use it because they don’t fully understand it yet.

The new study, Notes from the AI frontier: Applications and the value of deep learning, shows tremendous potential for the technology in the automotive, electronics, aerospace, defense, chemicals, agriculture, oil and gas, and other industries. It suggests that many executives in those industries are already adopting it.

“In the Fortune 500, we’re seeing a significant shift toward taking advantage of artificial intelligence and deep learning applications,” Mehdi Miremadi, a McKinsey partner and co-author of the study, told Design News. “It is, without a doubt, one of the most prominent areas of focus in the last two years for every industry.”

|

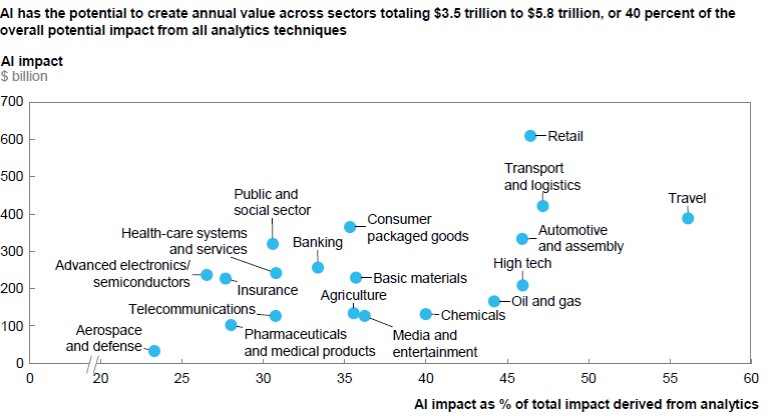

Artificial intelligence and deep learning have the potential to create trillions of dollars in value for a broad variety of engineering-driven industries. (Image source: McKinsey Global Institute) |

The study predicts that AI technology will have a tremendous financial impact on those industries. In automotive and assembly, for example, the paper’s authors expect AI and deep learning to generate about $300 billion in annual value. They also expect it to generate about $200 billion annually in electronics, $200 billion in chemicals, $100 billion in oil and gas, and about $25 billion a year in aerospace and defense.

The Benefits of Better Forecasting

One key area of application is predictive maintenance, the authors found. Using massive amounts of data from around a factory, for example, AI-based software can more accurately identify the assets and machinery that might be at risk of breaking down. And although many manufacturers are already doing predictive maintenance without AI, the authors believe they could do better with it.

“Using old types of analyses, you maybe could predict a 70% likelihood of a breakdown,” Miremadi said. “But with AI, you might go to 90% or even 95%. And that 20% difference has a significant value attached to it."

RELATED ARTICLES:

Other key areas of opportunity are inventory optimization and materials procurement. By using AI to do better forecasting, Miremadi said, manufacturers could streamline their production and supply chain management. “A lot of the inefficiency in the manufacturing and supply chain comes from not fully understanding what the demand will look like in the coming months and years,” Miremadi told us. “Using analytics and big data, you can develop a better perspective on demand and supply forecasting.”

Product developers could also benefit from AI and deep learning, the authors concluded. Today, they said, new product iterations typically emerge over a period of years, based on feedback from customers. But with AI, product developers could speed up that process. “One of the things AI can do is expedite that feedback loop,” Miremadi said. “Optimizing the feedback loop is advantageous, not only for the manufacturer, but for society at large.”

Miremadi added that some developers are already working on ways to integrate AI capabilities into their design software.

Pilot Purgatory

Understandably, however, many executives and engineers are hesitant to take full advantage of artificial intelligence and deep learning, Miremadi said. Their first instinct is to run pilot programs. Even when AI’s worth is proven, however, many executives still prefer to run more pilot programs instead of adopting it broadly. “Often, we see this in Fortune 500 companies,” Miremadi noted. “They’ve read about AI, and they may even have pilots running. But they run into what we call pilot purgatory—just let me do one more pilot.’”

Many executives hesitate because they don’t fully understand the AI mechanism, Miremadi said. And they won’t commit significant resources to anything they don’t fully understand. In those situations, change may be slower. “There are cultural components to the way data-driven decisions are made in an organization,” Miremadi said. “So on a tactical, day-to-day basis, a cultural shift will need to happen.”

Still, Miremadi expects growth of AI and deep learning to continue at a fast pace. The reason lies in the results. “There’s a huge area of opportunity here,” he said.

Senior technical editor Chuck Murray has been writing about technology for 34 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and auto.

|

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)