New Composite Recycling & Repair Method is Easy & Cheap

A cheap and easy new technique from Georgia Tech can recycle almost 100% of the materials in some types of thermoset epoxy-based carbon fiber composites, and also functions as a repair method for surface damage.

August 18, 2016

This past spring saw a lot of new methods for recycling and sometimes even repairing carbon fiber-reinforced composites. Some of them are still in the earlier stages of R&D at university labs, and some require the use of entirely new processes for manufacturing the composites in order to thoroughly recycle them. Now there's a different technique from Georgia Tech that can recycle almost 100% of the materials in some types of thermoset epoxy-based carbon fiber composites, and also functions as a repair method for surface damage.

Recycling and repairing composites are two of the bugaboos that have prevented their wider use in high-volume automotive manufacturing of production cars. To date, most recycling methods in use haven't been able to restore the original mechanical properties of fibers and polymer matrix materials. New methods for recycling and repairing these notoriously difficult materials, especially the carbon fiber variety, could also be a boon to industries like aerospace.

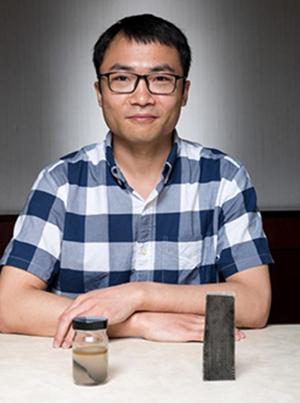

Former Georgia Tech mechanical engineering postdoctoral researcher Kai Yu sits in back of a section of carbon fiber composite immersed in an alcohol solution. A new technique from Georgia Tech can recycle almost 100% of the materials in some types of thermoset epoxy-based carbon fiber composites, and also functions as a repair method for surface damage.

(Source: Rob Felt, Georgia Tech)

The new Georgia Tech method addresses two different challenges that traditional carbon fiber composites pose for recycling, according to Jerry Qi, a professor in mechanical engineering at Georgia Tech leading a team of researchers who are affiliated with the university's Renewable Bioproducts Institute. "The polymer matrix is usually crosslinked, just like the rubber, and it can't be simply melted; it's very hard to strip away the polymer to reclaim the embedded carbon fibers, which are more valuable to recycle," Qi said.

The researchers decided to look at carbon fiber composites that use vitrimer epoxy for the polymer matrix. Under certain conditions, the dynamic bonds in these epoxies can alternate their structure without losing the integrity of their network.

READ MORE ARTICLES ON COMPOSITES:

The team described their work in an article in Advanced Functional Materials. In the new method, vitrimer epoxy-based composites are immersed in an alcohol solvent and the temperature is raised. Because the solvent's molecules are small, they can participate in bond exchange reactions within the covalent adaptable network of the epoxy, which dissolves, breaking the long polymer chains of the vitrimer into small segments.

Once the epoxy is dissolved, the clean carbon fibers can be reclaimed undamaged: they have the same mechanical properties and dimensions as virgin fibers. Heating the dissolved solution even further makes the epoxy matrix repolymerize, making it possible to fabricate a new generation of composites using the same epoxy and the recycled fiber.

The team also found that composites with surface damage could be repaired by the process. Plus, both the repaired and recycled composites have the same mechanical properties as fresh materials. Because the method is simple and straightforward, easy to operate, and can be easily scaled up, it could have immediate industrial applications, said Kai Yu, lead author of the article and a former postdoctoral researcher in mechanical engineering at Georgia Tech.

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 29 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

About the Author(s)

You May Also Like