Liquid Rocket Engine Components Aim to Blast into Space with Additive Manufacturing

Two member of LSU’s Mechanical Engineering faculty are working with NASA to employ additive manufacturing processes to reduce cost and lead times for its launch vehicles and propulsion systems.

June 20, 2022

NASA’s launch vehicles and propulsion systems must survive extreme thermal, dynamic, pressure, and environmental loads. Such complex systems typically consist of materials and alloys that may be costly and challenging to manufacture. However, additive manufacturing (AM) may be used to produce parts that can cost 50% less than those made with traditional manufacturing, and they can also be produced two to 10 times faster, according to experts at LSU College of Engineering. Such additively manufactured parts may also be made in a few months or even weeks, compared with traditionally manufactured parts that could take up to a year to make.

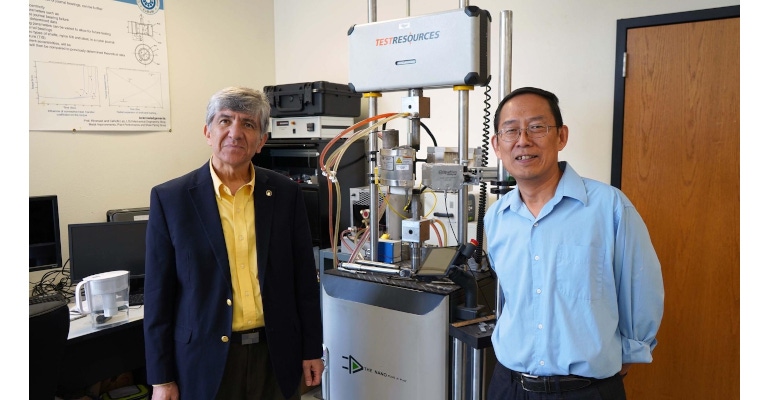

To explore the use of AM technologies, LSU Mechanical Engineering professors Shengmin Guo and Michael Khonsari are working with NASA and LaSPACE. Their work is possible thanks to a NASA Established Program to Stimulate Competitive Research (EPSCoR) and Louisiana Board of Regents grant. The project aims to provide NASA and industry with detailed datasets regarding thermophysical properties of the metallic AM parts.

“Our goal through EPSCoR and other partnerships is to advance technologies, including novel alloys, for our missions and commercial spaceflight partners,” said Paul Gradl, NASA principal engineer at Marshall Space Flight Center in Huntsville, AL, in a prepared statement. “Part of our role is to understand the additive manufacturing processes better and provide accessible data so that NASA and industry can make better use of these processes and novel alloys.”

For the past 18 months, Guo and Khonsari have been experimenting with alloys used in liquid rocket engine components made by AM methods, such as laser powder-bed fusion (L-PBF) and laser powder-directed energy deposition (LP-DED) methods, according to the statement. "L-PBF metallic 3D parts are fabricated by sequentially and selectively melting thin powder layers according to CAD-directed laser scanning strategies. Multiple laser line scans form the desired 2D section shape, followed by multiple powder deposition/laser irradiation cycles that generate complex 3D metal/alloy parts. LP-DED allows for large AM parts to be fabricated with a deposition head attached to a robot based on a CAD-directed toolpath," it was reported.

The project entailed conducting thermal and mechanical property measurements on more than 30 AM alloys and processes and established protocols for sample preparation, thermal and mechanical property testing, material characterization, and data analysis. “We have a lot of complex parts that have internal features and channels that were traditionally made from multiple joining operations (welding and brazing) to fabricate a component,” Gradl said. “As additive manufacturing processes and metal alloys mature, we must have good understanding of the properties to design for these additive processes that include mechanical and thermophysical properties.”

Thermophysical properties are a critical design element, and NASA required a substantial dataset for materials used in additive manufacturing processes, which is where the EPSCoR grant filled a gap, Gradl reported. For instance, thermal conductivity is a key thermophysical property, particularly in high-temperature components, such as combustion chambers, where heat transfer is critical for the alloy being used.

The team also conducted mechanical testing to provide mechanical property measurements using the LSU Center for Rotating Machinery (CeRoM) equipment in the LSU Shared Instrumentation Facility. CeRoM houses state-of-the-art fatigue-testing equipment, including rotating bending, fully reversed bending, torsion bending, and tension compression combined with torsion testing apparatuses.

“EPSCoR is excited to be associated with this research,” said Jeppie Compton, NASA EPSCoR project manager in a company statement. “What is lab research today will one day be normal business, and with this database of properties that the team did methodical studies on, NASA and our industry partners could have a huge advantage for decades to come.”

About the Author(s)

You May Also Like