Food Gets Automated. Try These 3D Printed Food Inks and Robot-Created Tacos

Food gets automated with manufactured tacos and 3D printed pureed foods for medical patients.

July 19, 2021

New developments in automation and additive manufacturing are changing how food gets prepared. In one case the improvements are to help patients with swallowing problems; in another case, we see a new twist on fast food.

Creating 3D Printed Food to Solve Swallowing Issues

Singapore researchers have developed a method for printing fresh vegetables. The goal is tastier, more nutritious food for patients with swallowing difficulties.

Researchers from Nanyang Technological University, NTU Singapore, Singapore University of Technology and Design, and Khoo Teck Puat Hospital have developed a new way to create “food inks” from fresh and frozen vegetables, that preserves their nutrition and flavor better than existing methods.

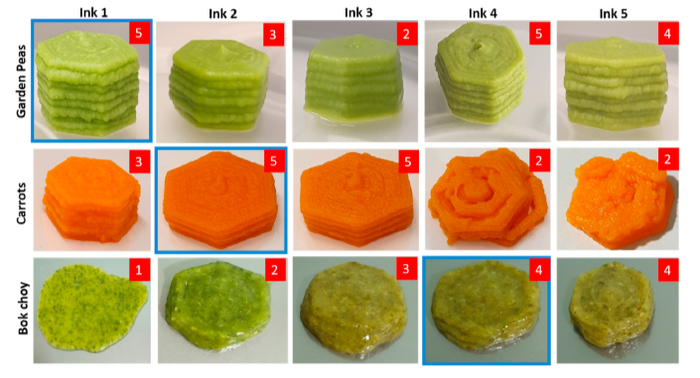

Food inks are usually made from pureed foods in liquid or semi-solid form, then 3D-printed by extrusion from a nozzle, and assembled layer by layer. Pureed foods are usually served to patients suffering from swallowing difficulties known as dysphagia. To present the food in a more visually appetizing way, healthcare professionals have used silicone molds to shape pureed foods, which is labor and time-intensive and requires storage.

Tastier Food Through Additive Manufacturing

Researchers solved this issue by using 3D printing to better preserve the nutrition of the food. The process can also be used to make the food more palatable. The result of these advancements can lead to increased meal consumption by patients who otherwise would find the pureed foods unpalatable.

Additionally, the team discovered that vegetables could be broadly classified into three categories, each requiring a different hydrocolloid treatment to become printable. Garden peas, carrots, and bok choy were chosen as representatives in each category, requiring no HCs, one type of HC, and two types of HCs, respectively – as the image shows.

Robots Come to Taco Production

In another world of food-meets-machine, Austin Automation Design has developed Tacomation, an automated food assembly line for tacos, burritos, and bowls that can save restaurant operators potentially millions of dollars per year in labor and food costs.

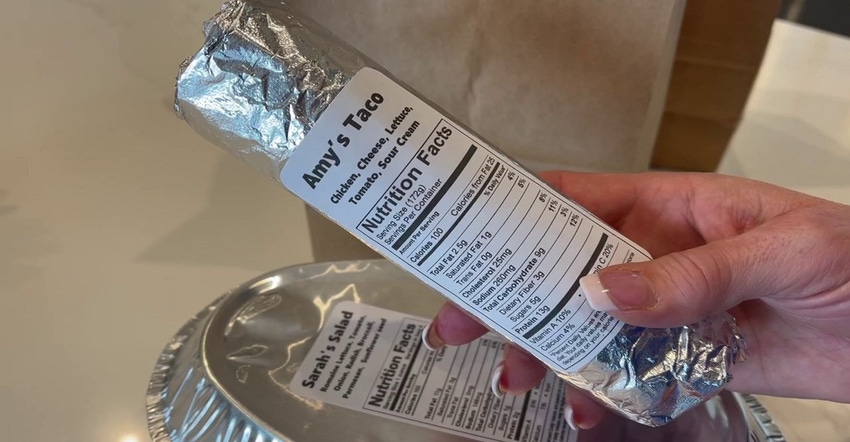

Starting with scratch-prepared food, customized orders made via a mobile app take only seconds to be automatically assembled, made to customers’ personalized nutritional specs every time. Tacomation also offers restaurant operators up-to-the-minute inventory tracking and product consistency.

The company was able to use existing automation technology to create an automated fast-food operation. "We've taken technology that exists on an industrial scale - automation - and brought a smaller-scale solution to the quick-serve restaurant industry, starting with our favorite dish: the taco," Doug Foreman, CEO of Austin Automation Design, told Design News. "An automated food line can save in both food and labor costs, potentially doubling a restaurant owner's bottom line in just one year. It also allows staff to focus on food preparation and guest relations while ensuring the health, safety, and quality."

Customers can place their order on a mobile app while the automated food line crafts the order to their exact specifications. Each item is labeled with its name and its nutritional statement. Customers can then drive up to a digital locker for touchless pickup, avoiding the wait at a drive-through window.

Rob Spiegel has covered manufacturing for 19 years, 17 of them for Design News. Other topics he has covered include automation, supply chain technology, alternative energy, and cybersecurity. For 10 years, he was the owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like