Want to Reduce Energy Use in Manufacturing? Try 3D Printing

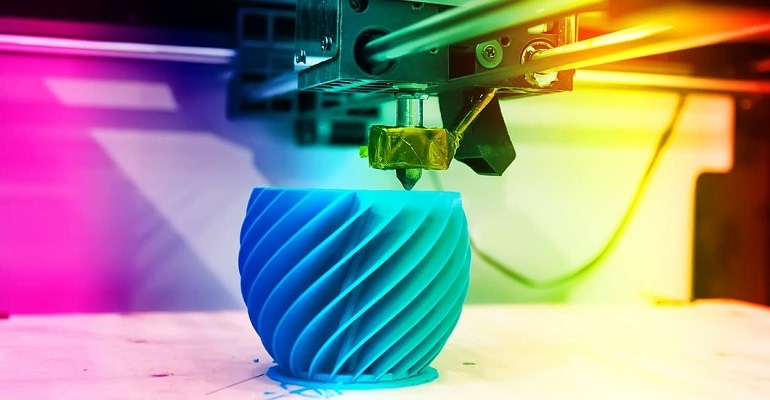

3D printing requires less energy in production than traditional manufacturing. It also consumes less energy in the design process.

November 8, 2021

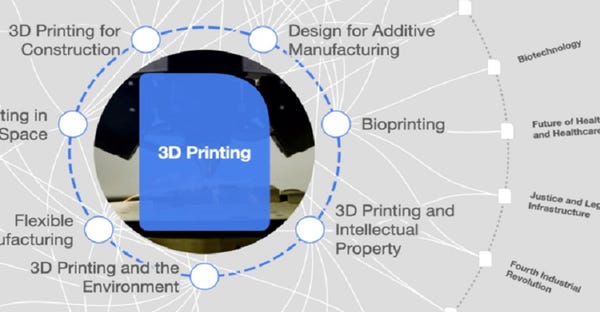

This is part two of a three-part series on the sustainability of 3D printing. The first article was Time for Clean Production Methods? 3D Printing Could Be the Solution. Part two looks at the use of energy in the additive manufacturing process and the energy efficiency in the design functions of 3D printing.

Additive manufacturing offers a reduction in carbon dioxide emissions. 3D printing is a more efficient process than machining or casting. Less energy is required to create the products, especially when production includes merging parts. Part consolidation itself offers long-term fuel savings and fewer emissions when it comes to producing products.

A Michigan Technological University study found 41-64% less energy was used to 3D print an object compared with manufacturing it overseas and shipping it to the US. The net result of using additive manufacturing in the US is fewer materials required and a reduced need for shipping.

3D Printing Process Consume Less Energy than Traditional Manufacturing

As well as the process consuming less energy, additive manufacturing requires less energy to support production. “The 3D Printing process consumes less energy part-for-part than traditional manufacturing,” Guayente Sanmartin, global head and general manager of the HP 3D Multi Jet Fusion Business, told Design News. “Less energy is needed when parts are printed on-demand, storage costs are cut, and less work energy needs to be spent on parts that can be printed overnight. Energy reduction takes place across the product lifecycle.”

Sanmartin noted there are several production processes in 3D printing that consume less energy than traditional manufacturing:

In pre-production, 3D printing can dramatically reduce the need for tooling, which requires high quantities of energy to be manufactured.

During production, the number of sub-assemblies is lowered, reducing the overall energy required to mass-produce products.

In service and maintenance, 3D printing enables manufacturing on-demand, which reduces the need to store parts over a multitude of years, removing the energy required to maintain parts over time.

Sanmartin also noted that HP had developed 3D printing technology that contributes to sustainability. “Compared to selective laser sintering (SLS) and fused deposition modeling (FDM) technologies, Multi Jet Fusion technology can reduce the overall energy requirements needed to attain full fusing and reduce the system requirements for large, vacuum-sealed ovens. The Multi Jet Fusion technology uses less heating power than SLS systems for better material properties and material reuse rates, minimizing waste.”

Design Process Supports Sustainability

Much of the design process for additive manufacturing is carried out on computers. Advances in computer simulations have made it possible to identify where parts can be improved. The 3D printing design process also allows users to identify where a part might fail, meaning fewer prototypes are required and less waste is generated.

Also, designs can easily be shared digitally and parts printed nearby or onsite. This greatly reduces transportation costs and reduces the energy spent on shipping. With traditional manufacturing, both raw materials and final products need to be shipped over long distances, which increases carbon dioxide emissions. “We no longer have to ship parts across the country. Instead, we can ship a file for a part to be produced on-site,” said Sanmartin. “This is where reduction in transportation footprint comes into play and helps to supplement the sustainability benefits of 3D printing. And, in pre-production, 3D printing dramatically reduces the need for tooling, which requires high quantities of energy to be manufactured.”

Another area of energy conservation is in the prototyping process. Generative design tools cut much of the energy-consuming testing and trial-and-error involved in creating a product for traditional manufacturing. “Design plays a critical role in determining environmental impacts – and software is certainly a component of that,” said Sanmartin. “With advances in software, engineers can design and iterate on prototypes, eliminating the number of times they need to be physically created. This naturally cuts down on material use and energy dedicated to part production.”

About the Author(s)

You May Also Like