New Strong Seaweed Goo Makes a Great Cover for Wounds and Soft Robots

‘Homocomposite’ materials developed by NC State researchers are derived from alginate and can be fabricated using 3D printing.

June 7, 2021

Researchers have used 3D printing to develop a type of strong and flexible jelly-like hydrogels derived from materials found in seaweed by combining different properties of the same material for optimal composition.

A team from North Carolina State University (NC State) developed the materials, called homocomposite hydrogels (HHGs), which are comprised of alginate components used in different ways. Alginates are chemical compounds found in seaweed and algae which already are used as common thickening agents and for wound dressings.

The materials differ from typical hydrogels—or materials with a strong basis in water—in that they are not soft and brittle, which is typical, noted Orlin Velev, a distinguished professor of chemical and biomolecular engineering at NC State. The nano-sized networks of alginate from which they are derived is what gives them their particular flexibility and strength by creating “two hydrogels in one,” he said.

“One is a particle hydrogel and one is a molecular hydrogel,” Velev explained in a press statement. “Merged together they produce a jelly-like material that is better than the sum of its parts, and whose properties can be tuned precisely for shaping through a 3D printer for on-demand manufacturing.”

Material Composition and Use

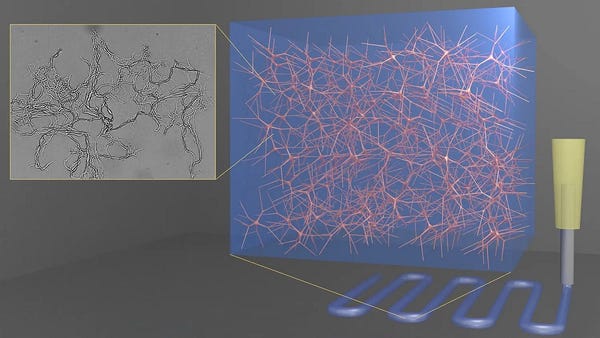

The HHGs are created by reinforcing a molecular alginate gel is by a colloidal network of hierarchically branched particles of alginate called soft dendritic colloids (SDCs), researchers explained in an abstract for a paper published on the research in the journal Nature Communications.

“The reinforcement of the molecular gel with the nanofibrillar SDC network of the same biopolymer results in a remarkable increase of the HHG’s mechanical properties,” researchers wrote.

“We are reinforcing a hydrogel material with the same material, which is remarkable because it uses just one material to improve the overall mechanical properties,” noted Lilian Hsiao, an assistant professor of chemical and molecular engineering at NC State and co-author of the paper, in a press statement.

Researchers envision a number of applications for the materials. Because of alginate’s history of use in wound dressings, the HHGs can be used as “a strengthened 3D-printed bandage or as a patch for wound healing or drug delivery,” Hsiao said.

Use in food products as a thickening agent as well as a material to develop soft robots also are potential applications for the new HHGs.

The team will continue its work to improve the materials and their application by finetuning the fabrication of the homocomposites in ways that advance not only the way they are 3D-printed but also how they can be used in biomedical applications or biomedical injection materials, Velev said.

Researchers also believe the technique they developed can be used with other types of gels found in coatings and other consumer products, so will explore these opportunities as well, he added.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like