GM Pushes Its Long Experience with 3D Printing into Additive Manufacturing

GM is exploring options for adding additive manufacturing to its production processes.

January 18, 2021

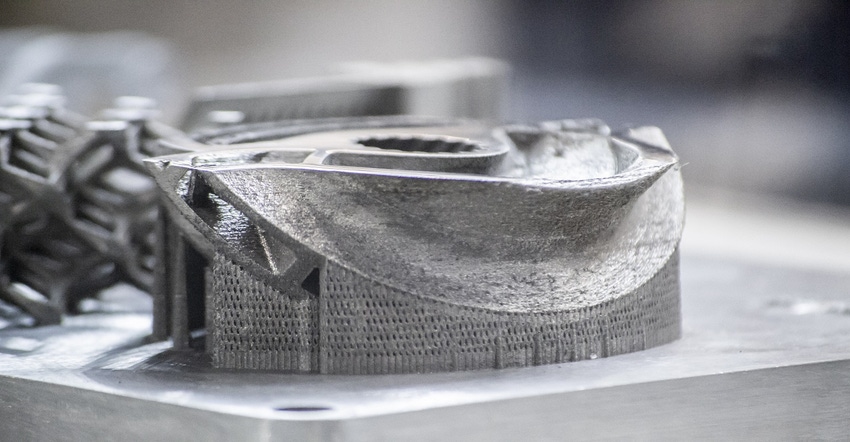

General Motors has a long history with 3D printing – going back more than 30 years. The automaker was one of the first companies to introduce 3D printing and generative design into its prototyping activities. More than 75% of the parts in the prototype of its 2020 Chevrolet Corvette were 3D printed, and GM now has 3D printers installed in many production facilities around the world. GM is now experimenting with ways to move beyond prototyping and into production-related applications like tooling.

The company is taking a practical approach with 3D printed production, trying to answer the question: Can additive manufacturing fit into GM’s overall manufacturing world. “We’re looking at 3D printing with sobering analysis rather than hype. We’re disciplined in making sure there is a real business case,” Ron Daul, GM’s director of additive manufacturing, told Design News. “We’re looking at quality challenges. Vehicle quality is important, so we’re looking whether 3D printing can fit with our internal standards and safety standards to see if additive manufacturing is right for us.”

Materials Matter

Part of the process of evaluating additive manufacturing is looking at the available materials. “We’ve educated our engineers about additive, and now we’re educating our suppliers and learning from our suppliers,” said Daul. “We’re developing an ecosystem that includes metals and polymers.”

As for the specific materials, GM is working with a variety to determine what’s appropriate for production. “Some of what’s being done with 3D in aerospace is with high-end polymers. So we’re looking at that,” said Daul. “We’ve also been focusing on nylon. We’d love to get into polyethylene. We’re also working with Stratasys, and that plugs us into other materials. We’re also looking at steel and aluminum.”

Building an Additive Ecosystem

GM has bet on the advantages of 3D printing by adding 17 production-grade Stratasys FDM 3D printers to its fleet. A big test for 3D printing came last April when GM entered into a contract with the U.S. Department of Health and Human Services to deliver a 30,000-unit order for critical care ventilators by the end of August. The company was able to quickly manufacture tooling fixtures in one day using Stratasys 3D printers.

That’s production, but it’s not cars. In the product space, GM has been using 3D printing to create functional prototypes to move vehicles to the testing process quicker. “We’re also diving into free-form part design, consolidating parts. We’re using 3D printing to remove the constraints of molding or injection,” Ali Shabbir, an engineer and global innovation lead in additive design and manufacturing for GM, told Design News. “3D printing is an involved process. You run into challenges with the size of the part as well as costs considerations. Will the part stand on its own? Is it too expensive compared to other forms of manufacturing?”

Fitting AM into Automobile Production

Then there’s the question of whether additive fits into GM’s overall production environment. “We look at 3D printing from design validation, and we hadn’t yet taken most of the steps to get there with production. Most auto companies haven’t taken those steps,” said Daul. “We’re still challenged by some of the hype that says additive works for everything. We’re challenged by machines that are too slow, materials that are too expensive, and by the changeover difficulties between products.”

Those concerns haven’t slowed down GM’s work in developing the potential for additive as part of auto production. The company’s investment in 3DP technology is impressive. “We’re never dormant in developing additive,” said Daul. “We have some of the smartest and best GM engineers working on it. We have an application base with 700 engineers in additive manufacturing. We have an exciting new building we’re working in right now.”

GM’s Future with Additive Manufacturing

As part of bringing additive manufacturing into the GM world, the company is planning to take 3D printing into schools. “The future for additive in automotive is pretty bright,” said Daul. “We need to find a way to get 3D printers into our schools, even grade schools. It needs to be integrated into the curriculum. Kids think it’s pretty cool. We have to get them interested in manufacturing with 3D printing.”

Getting the technology into schools will create a generation that’s at home with 3D printing. “We need additive centers and curriculum since it’s different from traditional design and production,” said Daul. “I would put a stake in the ground for GM’s ability to create an ecosystem for an additive future. We see a lot of possibilities for 3D printing in our business.”

Rob Spiegel has covered manufacturing for 19 years, 17 of them for Design News. Other topics he has covered include automation, supply chain technology, alternative energy, and cybersecurity. For 10 years, he was the owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like