Carbon 3D-Prints Test Swabs, Face Shields to Help Relieve COVID-19 Shortages

Silicon Valley–based digital manufacturing company Carbon announced today that it is producing more than one million 3D-printed nasopharyngeal swabs per week for COVID-19 testing. It has also partnered with adidas to print and donate PPE face shields to U.S. healthcare workers and first responders.

April 9, 2020

A Carbon L1 3D printer. Image source: Carbon

Digital manufacturing company Carbon announced today that it is producing around one million 3D-printed nasopharyngeal swabs weekly for COVID-19 testing and has the capacity to manufacture millions of them per week. Carbon also reported that it is collaborating with its customer adidas to print and donate face shields to U.S. healthcare workers and first responders.

The Resolution Medical Lattice Swab is manufactured using Carbon's Digital Light Synthesis (DLS) technology and KeySplint Soft Clear material from Keystone Industries. FDA-registered Resolution Medical is distributing the test swab, which has been classified as a Class I 510(k) Exempt in vitro diagnostic medical device.

|

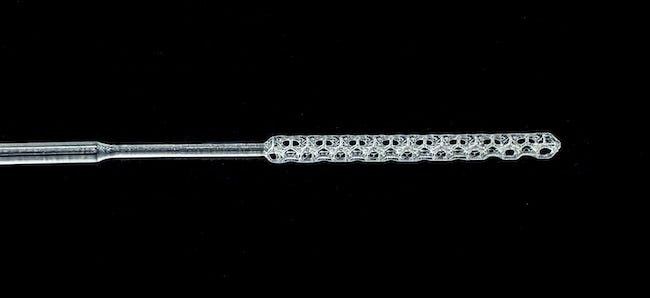

The hollow structure of the Resolution Medical Lattice Swab optimizes specimen collection. Image courtesy Carbon. |

As has been stressed repeatedly by medical experts and media covering the pandemic, patient testing swabs are among the most critical medical supplies needed by healthcare providers. Expanding the availability of testing supplies and testing frequency is a vital part of the timely identification of COVID-19 patients and helping to curb the pandemic’s spread, said Carbon in its news release.

The new Resolution Medical Lattice Swab has a conformal lattice design made with Carbon’s Lattice Engine software. The hollow structure of the lattice is designed for specimen collection efficiency, with a geometry that is also flexible to promote functionality and comfort for patients, said Carbon. The product is now undergoing clinical evaluation at multiple institutions, including Beth Israel Deaconess Medical Center (BIDMC), a teaching hospital affiliated with Harvard Medical School, and Stanford Medicine.

“We are proud to be collaborating with digital manufacturing company Carbon, to produce the Lattice Swab,” said Shawn Patterson, founder and President of Resolution Medical. “We have worked together urgently to get this product into the hands of healthcare workers to help address immediate needs for increased COVID-19 testing. At scale, we plan to supply over one million swabs per week.”

“Triggered by the COVID-19 pandemic, Carbon’s engineers and material scientists quickly sprung into action to identify the KeySplint Soft Clear material as having the right balance of properties to make a soft, flexible swab with appropriate strength that could be printed with precision using the Carbon M2 at 75 micron pixels,” said Dr. Joseph DeSimone, Carbon co-founder and Executive Chairman. The material is indicated for the fabrication of orthodontic and dental appliances in the United States, Canada, Europe, Australia, and New Zealand. The swabs, which are biocompatible and autoclavable, are currently printed hundreds at a time with a unique serialization present on each strip to facilitate traceability. “Resolution Medical, our production partner since 2018, has been amazing in leading the effort to launch the product,” added DeSimone.

|

In partnership with adidas, Carbon is producing and donating 18,000 face shields each week. Image courtesy Carbon. |

Carbon also announced today its partnership with adidas to produce PPE face shields using the material they developed for adidas' Futurecraft 4D athletic shoes. Silicon Valley–based Carbon is currently producing 18,000 face shields each week using its DLS technology, which grows objects from a pool of resin rather than creating them layer by layer. It has the capacity to produce more than 50,000 of the personal protective gear each week across its global network, said Carbon. The open source design is available on the company’s website and is free to use for anyone with a Carbon printer and material.

About the Author(s)

You May Also Like