Tiniest 3D-Printed Lenses Made with Femtosecond Lasers

July 12, 2016

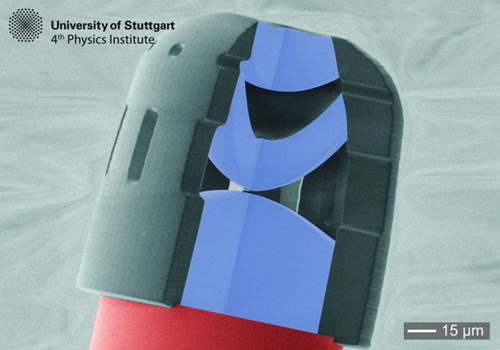

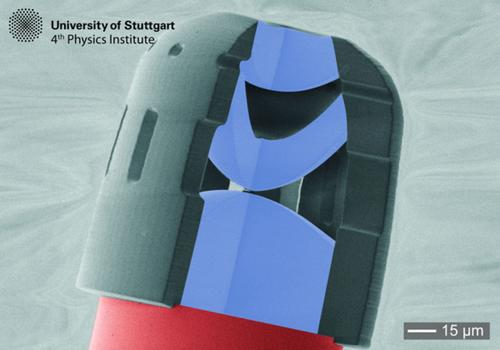

Researchers at the University of Stuttgart in Germany have produced the smallest optical lenses ever made using additive manufacturing (AM) processes. Combining the ultra-short laser pulses of a femtosecond laser with optical photoresist, the team created lenses with a diameter and height of only 125 microns (0.125 mm).

The extremely short pulses of the femtosecond laser, which are less than 100 femtoseconds in duration, made such high precision possible. The process can be used to create not only the more typical spherical shaped lenses, but also lenses with free-form optical surfaces.

The laser is focused using a microscope, and pulses are sent into a liquid photoresist placed on either an optical fiber or a glass substrate. Two photons of the red laser beam are simultaneously being absorbed and exposing the photoresist, which crosslinks and hardens the polymer. After washing away the unexposed photoresist with a solvent, the remaining hardened, transparent polymer forms the optical element.

This process makes it possible to construct lenses that have surfaces such as paraboloids or aspheres. It's also now possible to make optical systems that contain two or more lenses. These abilities combined could enable the construction of micro-optical imaging systems with multiple lenses in non-spherical shapes, with quality levels that couldn't be achieved before because of manufacturing constraints. Lenses like these are required for higher optical performance, and for aberration correction in situations with wide angles and large fields of view.

READ MORE ARTICLES ON 3D PRINTING:

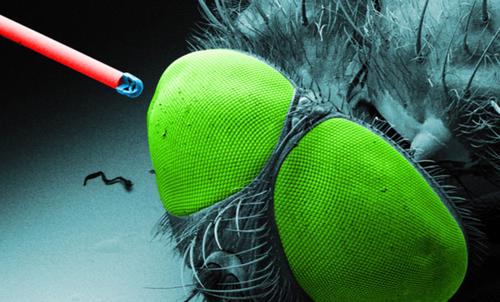

Graduate student Simon Thiele in professor Alois Herkommer's group at the Institute of Technical Optics in Stuttgart designed the optical lenses, working in the Stuttgart Research Center for Photonics Engineering. The tiny lenses were then printed onto optical fibers by graduate student Timo Gissibi in professor Harald Giessen's group at the 4th Physics Institute. These tiny lenses may be used to make miniature endoscopes for use inside the human body, or for inspecting the insides of small machine parts.

Gissibi also 3D printed miniature lenses and optical free-form surfaces directly on image sensor chips, producing extremely small image sensors. These could be used to make tiny cameras for use onboard insect-sized drones, such as the RoboBee designed by Harvard University's Microrobotics Lab. Other applications could include body sensors, surround cameras for cell phones, and tiny sensors for use in autonomous cars and robots.

The team also combined their tiny 3D-printed lenses with illumination systems, which could dramatically shrink the optics on an LED that concentrate light in a specific direction. Other possibilities include using miniature free-form optics to design illumination systems for unusual shapes such as ring-shaped areas, triangles, or elongated rectangles.

The researchers described their work in an article published in Nature Photonics.

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 28 years, covering manufacturing materials & processes, alternative energy, machine vision, and all kinds of communications.

About the Author(s)

You May Also Like