NAVAIR Flies First 3D-Printed Safety-Critical Part 14643

September 22, 2016

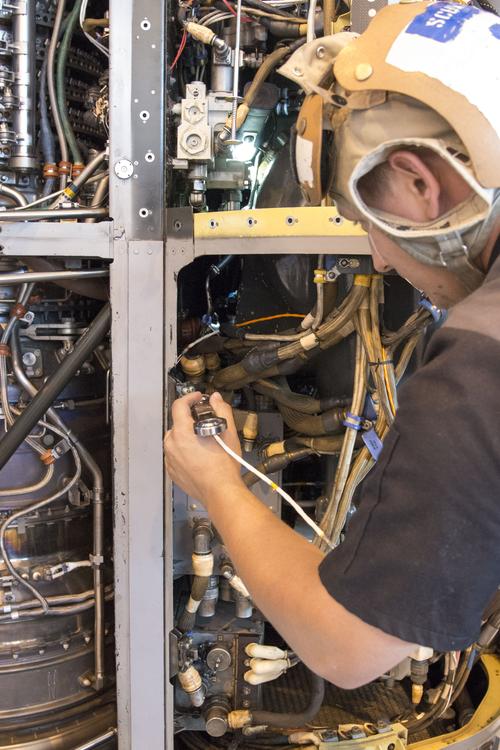

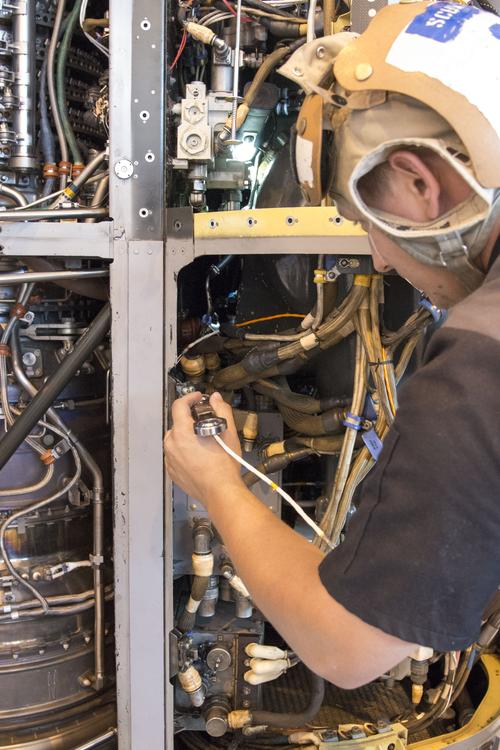

The first 3D-printed flight-critical part to fly on a Naval Air Systems Command (NAVAIR) plane was a success. The recent flight demonstration tested a titanium 3D-printed link and fitting assembly for the engine nacelle of an MV-22B Osprey military aircraft, which will stay on the plane for continued evaluation in future flights.

The test flight at Patuxent River Naval Air Station in Maryland was the first time a US Navy aircraft has flown with a part made with additive manufacturing (AM) that's considered essential to maintaining a safe flight. This metal link and fitting assembly is one of four that attach the V-22's engine nacelle to the primary wing structure.

Pilot Maj. Travis Stephenson, the MV-22 project officer, said, "The flight went great. I never would have known that we had anything different onboard." The standard flight performance envelope for the V-22 was used during the test flight. The aircraft is a tiltrotor military aircraft with both vertical takeoff and landing (VTOL) and short takeoff and landing (STOL) abilities, combining the functions of a helicopter with a turboprop.

The part was printed at the Naval Air Warfare Center Aircraft Division in Lakehurst, NJ. Engineers there, working with the Penn State Applied Research Laboratory, had already tested several V-22 components at Patuxent River Naval Air Station to validate their performance.

NAVAIR has used AM for prototyping for more than 20 years. More recently, it's begun broadening the use of AM to make end-use parts such as tools and non-flight critical components. Navy officials have stated many times that they want to deploy AM technology around the world so fleet maintainers and operators can make parts on demand. The technology could also be used by its industry partners so they can order parts digitally instead of ordering, stocking, and shipping finished parts.

READ MORE ARTICLES ON 3D PRINTING:

In the last 18 months, the team has started to "crack the code on using AM safely," said the Navy's AM integrated product team lead, Liz McMichael. "We'll be working with V-22 to go from this first flight demonstration to a formal configuration change to use these parts on any V-22 aircraft."

During the next year, McMichael and her team plan to build and test six safety-critical parts -- three made of titanium, including the V-22 link and fitting assembly, and three made of stainless steel -- for three US Marine Corps rotorcraft platforms: the V-22, the H-1, and the CH-53K.

[images via the US Navy]

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 29 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

About the Author(s)

You May Also Like