Nabbing the Benefits of Generative Design Without 3D Printing

Industrial manufacturer Claudius Peters is using generative design to inspire improved part shapes that are then produced using conventional manufacturing.

September 26, 2018

Generative design became the whispered theme at this year’s Autodesk Accelerate conference in Toronto last week. In product development, generative design functions to deliver two goals: reduced weight with equal or greater strength.

|

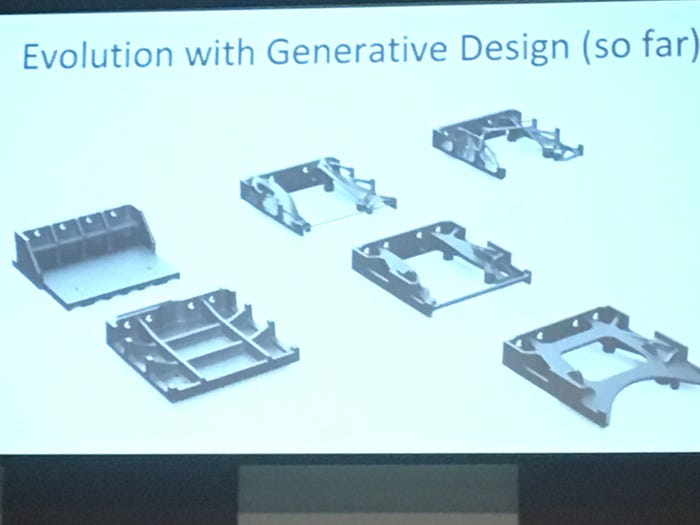

These design possibilities were produced through the generative design process. (Image source: Design News) |

Generative design is associated with 3D printing because the shapes possible with additive manufacturing expand beyond the limitations of conventional manufacturing, which involves machining or casting. However, at least one company has discovered that generative design can be used as a starting point for companies that want the benefits of generative design without the cost of 3D printing.

Revamping Engineering in the Digital Age

The German company Claudius Peters wanted to change its design process to improve its products. The company provides pneumatic conveyors, silos, clinker coolers, grinding mills, and packing systems, which can be found in cement, coal, alumina, and gypsum plants across the globe. “We like to do things at less cost, less weight, and less engineering,” Thomas Nagel, chief digital officer at Claudius Peters, explained during an Accelerate session. “We needed to get much better in all areas to reduce lead times, increase turnover, and lift customer satisfaction.”

In order to accomplish this, Nagel knew he would have to rethink the company’s engineering processes. “We used to have silos, where the engineering guys were separate from the manufacturing guys,” said Nagel. “We became convinced our know-how from yesterday would not prepare us for tomorrow. We needed to get agile, faster, and better.”

|

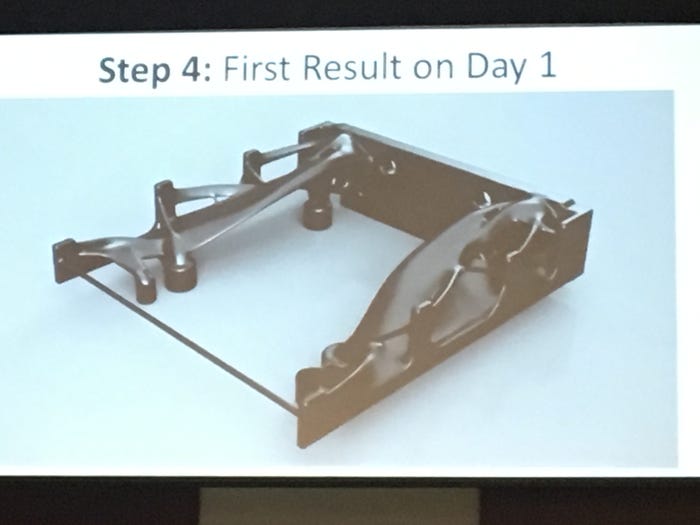

This was the optimal design that came from the generative design process. (Image source: Design News) |

Turning to Scrum to Improve Engineering

The company turned to Scrum to improve its engineering processes. Scrum is a concept that comes from the world of software development. In Scrum, you have teams of five to nine people who complete prioritized product-backlog items in iterations called sprints. These backlog items can be features, scenarios, or stories. A sprint is typically two to three weeks. “We looked at Scrum because we wanted to look at design differently,” said Nagel. “Design thinking at lean start-ups is often based on Scrum. We needed to learn new digital skills and learn how to get to the next step.”

Nagel realized that part of his challenge in changing decades-old processes would involve bringing in a new generation of engineers. Young engineers needed to be part of the change. “Our project team is like an incubator. It includes young people who are willing to change,” said Nagel. “We understood that the electric light didn’t come from the continuous improvement of candles. We needed to completely change how we were doing things. That’s why we tried generative design.”

Improving the Clinker Cooler

The first project they took up in the new approach was a part that goes on one of the company’s coolers. “We had to change the clinker cooler. The change had to be as cheap as possible,” said Nagel. “We wanted to reduce the weight and cost. The original design for the cooler parts was heavy duty.”

|

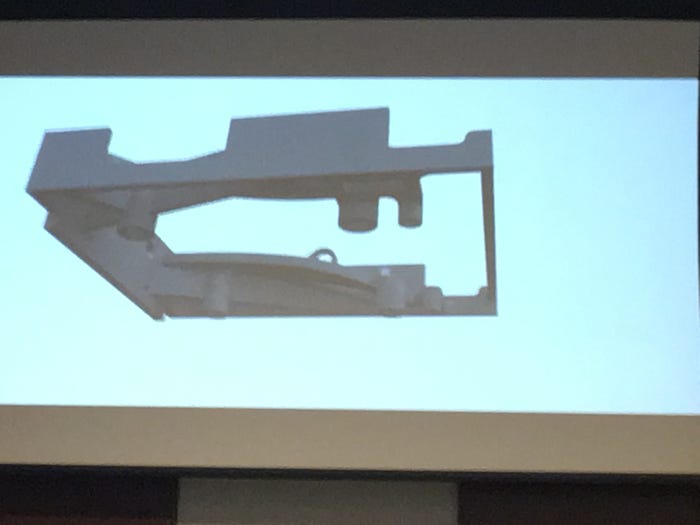

This part is the result of generative design being re-engineered for production using conventional manufacturing. (Image source: Design News) |

In order to come up with new engineering ideas, the SCRUM team turned to new design techniques. “We decided to change the way we think. We looked at the constraints and the loads. We brought in our IT, design, and engineering teams. We decided to try generative design,” said Nagel. “The result was surprising. We would never have come up with the design it produced. We examined it to make sure all the loads and constraints were correct. They were. And the part was 40% lighter.”

Reverse Engineering the Generative Design

Part of the overall goal for creating new parts was to make them affordable. “The process of creating the new part involved 3D printing, and we couldn’t bear the cost of 3D printing. So, we took the design and re-engineered it to support conventional manufacturing,” said Nagel. “We reverse-engineered the part and added in the information from the foundry. We found it needed some more material. So, we added more material. And even with added material, it was still 30% lighter. Our customers were excited.”

Since getting the positive result using generative design, the company has made it a standard process for parts design. “We continue to use generative design as an idea generator. We’re often very surprised with the result,” said Nagel. “Since we don’t want to do 3D printing, we reverse engineer the generative design and make the part conventionally. Maybe it only saves 30 percent of the weight instead of 40 percent, but it’s still a significant savings.”

RELATED ARTICLES:

Rob Spiegel has covered automation and control for 17 years, 15 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years, he was owner and publisher of the food magazine Chile Pepper.

|

About the Author(s)

You May Also Like